Summer Work Ban Compliance: Essential Cooling Gear and PPE for 2026

Preparing your site for the 2026 summer work ban is a matter of both legal and ethical necessity. It's about fundamentally protecting your workforce and ensuring your project's continuity. The core rule is clear: all outdoor work must stop from 12:30 PM to 3:00 PM between June 15th and September 15th. However, true compliance goes far beyond a simple work stoppage. It demands the right gear, a safe environment, and a proactive safety culture.

Forward planning is paramount. Waiting until May to procure essential cooling equipment and PPE is a recipe for supply chain issues and compromised worker safety.

Decoding the 2026 UAE Summer Work Ban

The summer work ban is a cornerstone of occupational safety in the UAE. For anyone managing a project, from a site foreman to a health and safety officer, a deep understanding of its requirements is non-negotiable. This isn't merely about adhering to a schedule; it's about fulfilling the legal and ethical duty of care owed to individuals working in the extreme summer heat.

This mandate, enforced by the Ministry of Human Resources and Emiratisation (MoHRE), is an unshakeable legal requirement with a proven track record of protecting workers for over two decades.

- Official Dates: The ban is enforced from June 15th to September 15th annually.

- Mandatory Break: All work performed under direct sunlight must cease between 12:30 PM and 3:00 PM.

- Core Requirement: Employers are legally obligated to provide shaded rest areas and adequate cooling provisions, including an ample supply of cold water.

To ensure clarity, here is a summary of essential compliance actions.

UAE Summer Work Ban 2026 at a Glance

| Requirement | Specification | Compliance Action |

|---|---|---|

| Work Stoppage | Cease all outdoor work from 12:30 PM to 3:00 PM. | Create and communicate a revised work schedule for the ban period. |

| Rest Areas | Provide accessible, shaded, and well-ventilated rest zones. | Set up rest tents or designated indoor areas with fans or cooling units. |

| Hydration | Ensure a constant supply of cool drinking water. | Install water coolers and provide personal water bottles. Monitor supply daily. |

| Worker Awareness | Inform all workers of the risks of heat stress and ban rules. | Conduct mandatory training sessions in multiple languages. Post informational posters. |

| Emergency Plan | Have a clear protocol for heat-related medical incidents. | Train first-aiders, ensure medical kits are stocked, and post emergency contact numbers. |

Mastering these fundamentals is the foundation of a safe and legally compliant summer season.

Why Compliance is More Than Avoiding Fines

While the financial penalties are significant, the true cost of non-compliance is far greater. A single incident of severe heatstroke can lead to tragic health outcomes, force project shutdowns, and inflict lasting damage on a company's reputation. Proactive compliance demonstrates a clear commitment to valuing your workers' wellbeing above all else.

The authorities maintain strict oversight. The UAE's heat stress prevention policies are highly effective, with the 2025 summer season achieving an impressive 99% compliance rate. For the small minority that disregards the law, penalties begin at AED 5,000 per worker, escalating to a maximum of AED 50,000. To understand the seriousness of enforcement, you can review the official work ban compliance statistics.

A Strategic Approach to Safety and Procurement

True compliance is rooted in strategic preparation, especially when sourcing the right UAE summer work ban safety equipment. Last-minute procurement inevitably leads to stock shortages, inflated prices, and the risk of acquiring substandard gear that fails to provide adequate protection.

Adhering to the midday work ban is not just about pausing work; it's about actively creating a safe environment during rest periods. This includes providing the correct cooling vests for construction, ensuring PPE standards in Dubai are met, and making hydration easily accessible.

This is where a specialist supplier like Yasu Trading becomes an indispensable partner. We offer more than just safety equipment; we provide a comprehensive range of municipality-compliant, breathable safety gear and cooling solutions specifically engineered for the demanding UAE climate. By addressing your procurement needs early, you ensure your team is equipped with high-performance gear well before the June 15th deadline. It is a strategic decision that guarantees compliance and promotes a safer, more productive worksite throughout the summer.

Getting a Real-World Handle on Heat Stress Risks

Preparing for the 2026 summer work ban cannot be effectively managed from an office. Real compliance begins with a boots-on-the-ground assessment of the site to understand where heat poses the greatest threat. A generic checklist is insufficient.

Your objective is to identify specific heat hazards that could endanger your team. This is not just a regulatory exercise; it is a critical process for preventing heat stroke, maintaining morale, and ensuring project continuity. A safe crew is a productive crew.

Pinpointing High-Risk Zones and Scenarios

Every worksite has a unique microclimate. A large-scale infrastructure project in the open desert near Abu Dhabi will have a different heat profile than a high-rise development surrounded by the reflective surfaces of the Dubai skyline. You must map these hot spots.

The most effective method is to walk the site during peak heat hours, even before the ban officially starts. Experience the conditions firsthand.

- Reflective Surfaces: Identify areas adjacent to glass-clad buildings, large metal sheets, or standing water. These surfaces act as mirrors, intensifying solar radiation and UV exposure.

- Stagnant Air Pockets: Locate poorly ventilated areas such as confined spaces, deep trenches, or enclosed indoor sections where air becomes trapped and superheats.

- Heat-Belching Equipment: Note the placement of generators, compressors, and heavy machinery. These units radiate significant heat, increasing the ambient temperature for nearby workers.

Consider a high-rise project in Dubai. Lower floors may be relatively cool, but upper levels where crews install facades next to reflective glass can quickly become dangerously hot. This level of granular analysis is essential for effective planning.

The most effective heat stress assessments consider more than just a thermometer reading. They integrate ambient temperature, radiant heat from surrounding surfaces, and the physical demands of the task. This holistic approach builds a true risk profile for every worker.

Sizing Up the Strain of Different Tasks

Not all work is created equal. A safety officer's next responsibility is to categorise tasks by their level of physical exertion. This allows for the precise allocation of appropriate protective gear and rest schedules.

The key factor is energy expenditure. Tying rebar or operating a jackhammer generates substantial internal body heat and is far more demanding than operating a crane from an air-conditioned cab.

A Quick Look at Task Exertion:

| Exertion Level | Example Activities | Key Risk Factor |

|---|---|---|

| High | Rebar tying, manual excavation, concrete pouring | Constant, tough physical work that leads to fast dehydration. |

| Moderate | Scaffolding assembly, carpentry, general plumbing | Steady physical effort with some breaks, but still a major risk. |

| Low | Site supervision, crane operation, security | Often stationary, but can mean long hours directly in the sun. |

Documenting these findings is crucial. For safety officers looking to implement a more structured system, our guide on building a construction risk assessment template can provide a valuable framework.

An Honest Look at Your Current Defences

Finally, conduct a candid assessment of your existing heat mitigation measures. You may have shade tents and water stations, but are they effective?

A shaded area that requires a ten-minute walk to reach is practically useless. A water cooler that is frequently empty is a failure of your system. Cooling stations must be conveniently located, consistently stocked with cool water, and provide a genuine respite from the heat.

This type of honest audit exposes gaps in your safety plan. It provides a clear, actionable list of what must be improved before the summer ban begins, enabling you to build a strategy that genuinely protects your people.

Picking the Right Cooling Gear and PPE for Extreme Heat

Once you’ve mapped out your site's heat risks, it's time to equip your team properly. Selecting the right Personal Protective Equipment (PPE) is not merely a summer work ban compliance task; it is a direct investment in your crew's health and your project's productivity. In the intense UAE summer, standard-issue safety gear is simply not enough.

Simply put, the right equipment keeps your team safe and focused. The wrong gear can create a false sense of security or even increase the risk of heat stress. Understanding the technical specifications is critical.

Going Beyond Basic PPE

Standard hard hats and safety vests are designed for impact protection, not for managing extreme thermal loads. Heavy, non-breathable materials trap heat and moisture against the skin, accelerating dehydration and fatigue. For the UAE summer, your procurement focus must shift to gear specifically engineered for heat and humidity.

This means seeking out smart features that augment the body's natural cooling processes.

- High UPF Ratings: Look for fabrics with a UPF 50+ rating. This is the industry standard for blocking harmful UV radiation and reducing the solar heat load on a worker's body.

- Advanced Moisture-Wicking: The material must actively pull perspiration away from the skin to the fabric's surface for evaporation. This process is essential for effective cooling.

- Serious Breathability: Air circulation is vital. Prioritise ventilated hard hats, vests with mesh panels, and breathable footwear to prevent the buildup of trapped, hot air.

To get this right, partnering with a supplier who understands the local climate is crucial. Sourcing high-quality, compliant gear from a trusted partner like Yasu is a critical step. We can guide you through the specific PPE standards Dubai and other emirates require, ensuring every item is fit for purpose.

The Science of Cooling Vests on a Construction Site

Cooling vests are a transformative technology for outdoor workers, but not all vests are created equal. The two main types are evaporative and phase-change, and understanding their differences is vital in the context of UAE's high humidity.

Evaporative cooling vests work by soaking them in water; as the water evaporates, it cools the wearer. While effective in dry climates, their performance is severely diminished in the humid coastal air of the UAE, where evaporation is slow.

Phase-change cooling vests are the superior solution for this region. They utilize special inserts that are frozen or refrigerated. These packs actively absorb body heat, maintaining a consistent, cool temperature for several hours, regardless of ambient humidity.

On sites in Dubai, Abu Dhabi, or Sharjah where summer humidity regularly climbs past 70%, phase-change cooling vests for construction are the clear winner. They deliver direct, reliable cooling that doesn't depend on an evaporation process that’s fighting a losing battle against the humid air.

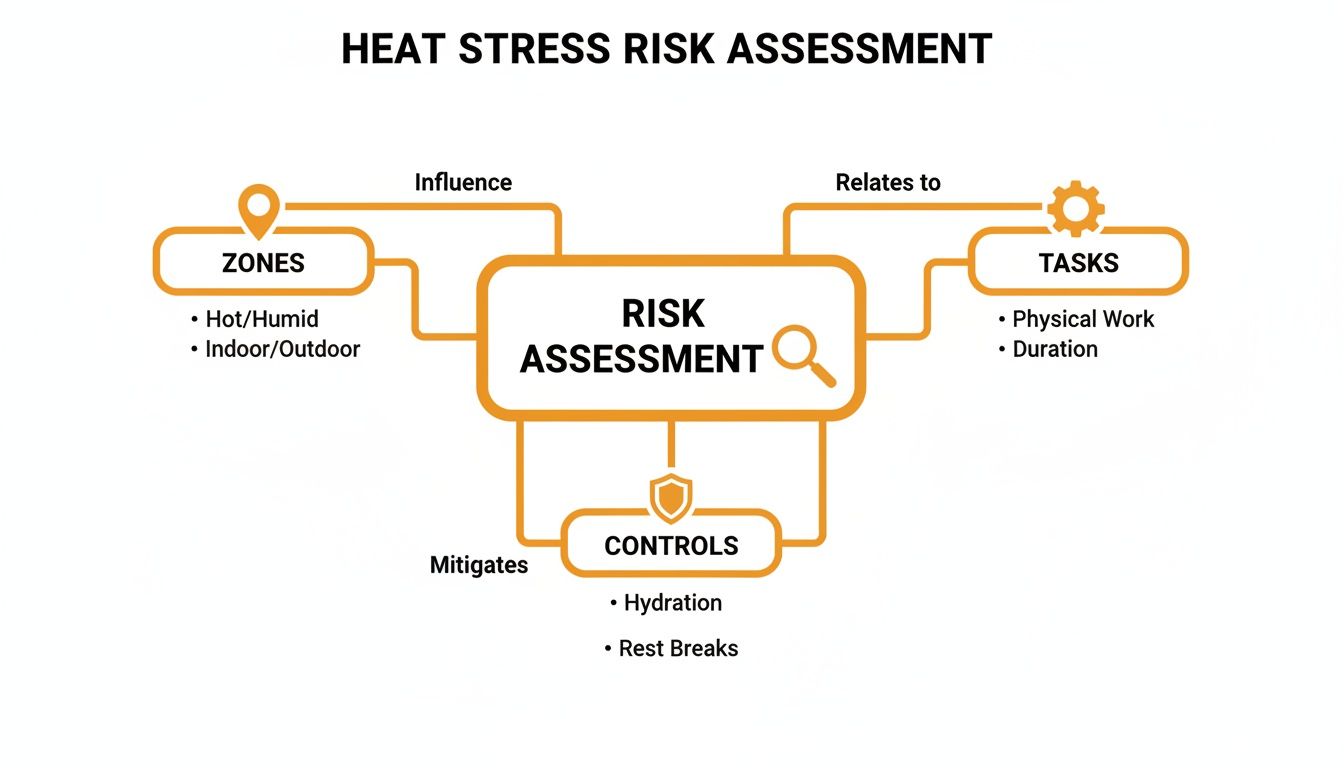

A proper risk assessment, as illustrated below, helps pinpoint exactly which zones and tasks require advanced engineering controls like these.

This process clarifies the need: identify high-risk areas and strenuous jobs first, which in turn dictates the specialised PPE required for deployment.

A Head-to-Toe Approach to Cooling

The most effective strategy for UAE summer work ban safety equipment is a holistic one. Each piece of equipment should work in concert to create a personal cooling system for the worker.

- Head Protection: Modern hard hats offer more than impact resistance. Seek out models with wide brims, attachable neck sunshades, and multiple ventilation ports to allow heat to escape.

- Eye Protection: Safety glasses or sunglasses must provide 100% UVA/UVB protection. Wraparound styles are optimal as they prevent sun and glare from entering from the periphery.

- Breathable Workwear: Prioritise lightweight, light-coloured, long-sleeved shirts and trousers made from moisture-wicking fabric with a high UPF rating.

- Ventilated Footwear: Safety boots should feature breathable linings. Trapped heat and moisture in footwear can cause blisters, discomfort, and become a significant distraction.

The widespread adoption of this high-specification PPE reflects the region's strong commitment to worker safety. While employers must provide basic amenities like shade and water, it is the proactive use of quality gear that has contributed to the consistent 99% compliance rate over the 21-year history of the Midday Break policy. You can learn more about the official guidelines on the UAE's Midday Break policies page on mohre.gov.ae.

Here’s a quick-glance checklist to help you dial in the specifications when sourcing your gear.

Essential Cooling PPE Specification Checklist

This table breaks down the crucial technical specs to look for when procuring PPE that’s truly built for the UAE’s summer conditions.

| PPE Category | Key Technical Specification | Yasu Recommended Product Type |

|---|---|---|

| Cooling Vests | Phase-Change Material (PCM) inserts that activate at a safe temperature (e.g., 15°C) and provide 2-4 hours of cooling. Must be non-toxic and flame-resistant. | PCM-based vests with multiple insert pockets for balanced cooling. |

| Headwear | ANSI/ISEA Z89.1 Type 1, Class C rated hard hat with integrated UV400 polycarbonate visor and adjustable ventilation ports. Lightweight polycarbonate or ABS shell. | Vented hard hats with wide brims and attachable neck shades. |

| Workwear | UPF 50+ rated fabric. Lightweight (<150 GSM), moisture-wicking polyester or modacrylic blends. Light colours (e.g., beige, light grey) to reflect sunlight. | Long-sleeve, high-visibility shirts with mesh underarm panels. |

| Eyewear | ANSI Z87.1+ impact rating. Lenses must provide 100% UVA/UVB protection. Anti-fog coating is essential for humid conditions. Wraparound design. | Polycarbonate wraparound safety sunglasses with polarised lens options. |

| Footwear | EN ISO 20345:2011 safety rating (S1P or S3). Breathable leather or synthetic upper with a moisture-wicking inner lining (e.g., Cambrelle). | Safety boots with breathable fabric panels and climate-control footbeds. |

Getting the procurement details right is foundational. If you want to go deeper on sourcing, have a look at our guide on finding the best safety equipment suppliers in Dubai.

Putting Your On-Site Compliance Plan into Action

A thorough risk assessment and a supply of new cooling gear are excellent preparations, but they are only the beginning. True summer work ban compliance is not about paperwork in an air-conditioned office; it is defined by the actions taken on the ground when the heat is at its worst.

Your plan is only effective when it is implemented consistently on-site, every day from June to September. This is the transition from theory to practice, fostering a safety culture where every individual, from the project manager to the newest labourer, understands their role. It is less about merely possessing equipment and more about ensuring its correct use, supported by systems that make safety the default choice.

Establishing Effective Cooling and Hydration Stations

Your cooling stations are non-negotiable safety hubs, not just an afterthought. A poorly located or unstocked station is not a minor oversight; it is a significant compliance failure.

For these stations to be effective, they must be:

- Strategically Located: No worker should have to walk far for water. A good rule is that a shaded rest area should be accessible within a minute or two from any work zone. On larger projects, this necessitates multiple, well-placed stations.

- Properly Equipped: Shade is the bare minimum. Enhance stations with industrial fans or misting systems. Most importantly, guarantee a constant, reliable supply of cool drinking water and electrolyte supplements to replenish fluids lost through sweat.

- Maintained and Monitored: Assign specific responsibility to an individual for checking and restocking every station before each shift begins. An empty water cooler at 11:00 AM indicates a systemic failure.

Treat your cooling stations as critical site infrastructure. They must be dependable and ready to perform when needed most.

Smart Scheduling and Supervisor Training

Beyond physical infrastructure, on-site execution relies on intelligent work planning and well-trained supervisors. The midday break is mandatory, but you can further minimise heat exposure through smart scheduling.

Schedule the most physically demanding jobs—such as concrete pours or rebar installation—for the cooler morning hours. Less strenuous tasks or indoor work can be allocated to the period leading up to the 12:30 PM break.

Equally critical is empowering your foremen and supervisors. They are your first line of defence. Train them to recognize the subtle, early signs of heat stress before it becomes a medical emergency.

A supervisor who can tell the difference between a worker who is just tired and one showing the first signs of heat exhaustion—like dizziness, confusion, or cramps—can prevent a medical emergency. This kind of proactive observation is the bedrock of a strong safety culture.

A robust Occupational Health and Safety Management System provides the essential framework for all these efforts, from initial risk assessments to emergency protocols.

Clear Communication and Emergency Readiness

Your plan is ineffective if your team does not understand it.

Post daily work schedules, break times, and heat stress warnings in multiple languages relevant to your workforce. Use simple graphics alongside text to illustrate hydration reminders and the symptoms of heat-related illnesses.

Finally, ensure every person on site knows the emergency procedure. Who should they contact if they or a colleague feels unwell? What is the number for the site medic? Post this information clearly at every cooling station and in all common areas.

The UAE's enforcement of the summer work ban is stringent, utilizing official inspections and community reporting to ensure compliance. MoHRE even provides a toll-free hotline at 80060 for reporting violations, which is a key factor in the nation's consistent 99% compliance rates.

When your plan is clear and well-communicated, you empower every worker to look out for themselves and their teammates. Compliance evolves from a top-down directive into a shared responsibility across the entire site.

Mastering Worker Training and Audit-Ready Documentation

Procuring the best cooling gear is a vital step, but its effectiveness hinges on comprehensive training and meticulous documentation. Without these, even the most advanced UAE summer work ban safety equipment may be used improperly, and your company remains vulnerable during inspections. This is where your compliance plan becomes an integrated part of your site's daily operations.

Effective training transforms your PPE investment from a compliance checkbox into an active safety strategy. It is not sufficient to simply issue a phase-change cooling vest for construction; workers must understand how to use, maintain, and maximise its benefits. Simultaneously, your documentation serves as irrefutable proof of your commitment to worker safety.

Creating Training That Actually Sticks

Effective training transcends a brief toolbox talk. To resonate with a diverse workforce, it must be hands-on, visual, and delivered in multiple languages. Your team must not only be able to recognise the signs of heat stress in themselves and their colleagues but also feel empowered to take immediate action.

Your training sessions should cover these key areas:

- Symptom Recognition: Use simple graphics and clear language to differentiate between heat exhaustion and the more life-threatening heat stroke.

- PPE Use and Care: Conduct practical demonstrations on how to properly use all equipment, from activating cooling vests to adjusting ventilated hard hats for optimal airflow.

- Hydration Strategy: Explain the critical importance of regular hydration and the role of electrolytes in preventing muscle cramps and fatigue.

- Emergency Drills: Rehearse the exact procedure for reporting a heat-related incident. Every worker must know who to contact and what steps to follow without hesitation.

To prepare your team for the 2026 summer work ban, it is beneficial to follow proven compliance training best practices. This approach fosters a culture of shared responsibility for safety.

Building an Audit-Proof Documentation System

When a MoHRE inspector arrives, your records are your primary defence. Detailed, organised documentation is not optional; it is the tangible evidence that your safety plan is being implemented daily. This is not merely about avoiding fines—it is about creating a data trail that can be used to continuously improve your own safety protocols.

Your audit file should be a living document, updated daily throughout the ban period. It should contain, at a minimum, the following clearly organised sections.

Your Essential Documentation Checklist

| Document Type | Key Details to Record | Why It's Critical |

|---|---|---|

| Training Attendance | Worker names, signatures, date, and topics covered (in multiple languages). | Proves every worker got the mandatory heat safety training. |

| PPE Distribution Logs | Worker name, item issued (e.g., cooling vest, neck shade), date, and signature. | Confirms every individual received the necessary protective gear. |

| Daily Water Records | Date, number of water coolers on site, and volume of water/electrolytes consumed. | Shows you are providing more than enough hydration. |

| Site Inspection Logs | Daily checks of cooling stations, shade availability, and first-aid kit readiness. | Demonstrates proactive monitoring of your on-site facilities. |

| Incident Reports | Detailed records of any heat-related issues, no matter how small, and the response. | Provides evidence of a clear and effective emergency plan. |

This level of detail is precisely what is required to satisfy PPE standards Dubai inspectors and other regulatory bodies.

Think of your documentation as the project's safety diary. It tells the story of your daily commitment to worker welfare, providing a clear, chronological account that stands up to scrutiny from both external auditors and internal reviews.

This process is simplified when you partner with a knowledgeable supplier. At Yasu Trading, we ensure all our safety gear is accompanied by the necessary technical data sheets and product certifications. This information integrates seamlessly into your records, confirming that your equipment meets or exceeds all local compliance requirements and strengthening your overall documentation.

Got Questions About the Summer Work Ban? We’ve Got Answers.

When navigating the UAE summer work ban, complexities often arise from specific on-site situations. Even seasoned project managers can encounter scenarios where the official guidance seems ambiguous.

Here are direct answers to the most frequent questions we receive from teams preparing for the summer season.

Are There Loopholes to the Midday Break Rule?

In short, no. However, there are strictly defined technical exemptions. The Ministry of Human Resources and Emiratisation (MoHRE) acknowledges that some critical operations cannot be halted without causing significant danger or damage.

These exemptions are reserved for tasks such as:

- Pouring a large concrete foundation that must be completed in a single, continuous operation.

- Conducting emergency repairs on essential public utilities, like a burst water main or a downed power line.

- Laying asphalt where an interruption would compromise the integrity of the surface.

Obtaining an exemption is not a simple matter of project deadlines; you must submit a formal application and provide technical justification for the necessity. Even with MoHRE approval, the employer's duty of care remains absolute. You must still provide cold drinking water, electrolyte solutions, and properly shaded, cooled rest areas. The core responsibility to prevent heat stress is never waived.

A word of caution: don't mistake project urgency for technical necessity. The rules are strict for a reason. Always operate as if the ban applies unless you have a documented, official exemption in hand.

Is Water Really Enough to Keep Workers Hydrated?

Water is the foundation of hydration, but it is not the complete solution. During the peak of a UAE summer, workers lose critical electrolytes like sodium and potassium through sweat, leading to rapid energy depletion and increasing the risk of heat exhaustion.

Relying solely on water is a common oversight. A modern hydration strategy must also replenish these lost minerals.

- Electrolyte Powders: These are highly effective and easy to distribute. Workers can mix them into their personal water bottles for convenient rehydration.

- Sports Drinks: Ready-to-drink options are also viable, but it is important to monitor sugar content. Low-sugar or zero-sugar formulations are preferable.

- Hydrating Foods: Do not overlook the benefits of food. Offering slices of watermelon or cucumber during breaks provides a natural source of hydration and essential minerals.

This approach goes beyond basic summer work ban compliance; it demonstrates a sophisticated understanding of worker physiology and provides the necessary support to keep them safe and healthy.

Can Technology Help Keep My Team Safe?

Absolutely. Technology has advanced far beyond simple reminders to "take a break." Modern solutions offer real-time data to help prevent heat stress before it occurs.

Smart wearable technology is becoming a powerful tool on forward-thinking construction sites. Devices like vests or armbands can monitor a worker's core body temperature and heart rate. If an individual's vital signs enter a hazardous range, an alert is automatically sent to the site supervisor.

This enables immediate intervention, allowing a supervisor to direct the worker to a mandatory rest and hydration break long before they might recognize the symptoms themselves. This proactive approach sets a new benchmark for meeting the high PPE standards Dubai and other emirates demand.

Over time, this data also reveals which tasks and site areas are most physiologically taxing, providing valuable insights for developing smarter, safer work plans for 2026 and beyond.

Your team's safety is the foundation of a successful project. Equipping them with top-quality, municipality-compliant gear is not optional—it is a fundamental responsibility. For a complete range of breathable workwear, advanced cooling vests, and certified PPE designed for the rigours of the UAE climate, you need a partner you can trust. Yasu Trading Co. LLC offers a comprehensive selection of solutions. Explore our catalogue and prepare your site for the 2026 summer work ban by visiting us at https://yasutrading.com.