Discover value engineering in construction projects: Boost ROI and quality

Value engineering in construction isn't just another buzzword for saving money. It’s a systematic and creative process aimed at getting the absolute most out of every dirham spent on a project. We're not talking about simply cutting corners or swapping out specified materials for cheaper alternatives. Instead, it’s about finding the smartest, most cost-effective way to deliver the required performance, quality, and reliability, all while meeting the demanding UAE construction standards.

What is value engineering in construction?

Value engineering is a disciplined methodology that challenges the 'why' behind every design choice to unlock hidden value. Think of it like a master chef tweaking a signature dish. They wouldn't just replace saffron with turmeric to cut costs—that would ruin the final product. A true chef would experiment with techniques or ingredient combinations to create an even better flavour profile, perhaps in a more efficient way. That’s the very essence of value engineering in construction projects.

This approach forces project teams to look far beyond the initial price tag and consider the building's entire lifecycle. For instance, a slightly more expensive HVAC system might slash energy bills for decades, delivering far greater value over its operational life. A solid grasp of construction project management practices is a great foundation for understanding just how critical this mindset is.

Value engineering is all about function. The first question is always, "What is this component supposed to do?" That's immediately followed by, "Is there a better, smarter, or more economical way to achieve that function without compromising an inch on quality?"

This philosophy sparks a proactive and collaborative spirit, bringing architects, engineers, contractors, and suppliers together right from the project's inception.

How is value engineering different from cost cutting?

It’s easy to confuse value engineering with old-fashioned cost cutting, but they are worlds apart. While both aim to lower expenses, their approach and ultimate goals are fundamentally different. Cost cutting is a reactive tactic to meet a tight budget, often sacrificing quality and long-term performance, whereas value engineering is a proactive, function-focused strategy.

To clear up this common misunderstanding, here's a direct comparison:

Value Engineering Compared to Traditional Cost Cutting

| Aspect | Value Engineering (VE) | Traditional Cost Cutting |

|---|---|---|

| Focus | Function-oriented: Maximising value (Performance/Cost) | Price-oriented: Reducing initial expenditure |

| Timing | Proactive: Applied early in the design phase | Reactive: Often done late in the project to meet a budget |

| Scope | Holistic: Considers the entire project lifecycle | Narrow: Focuses on individual item costs |

| Outcome | Quality is maintained or improved | Quality is often compromised |

| Mindset | Collaborative and creative problem-solving | Adversarial and often arbitrary |

In short, value engineering is a proactive strategy focused on preserving, and even enhancing, a building's functionality while optimising the cost to achieve it.

Let's look at a practical example.

- Cost Cutting: This might mean switching to a lower-grade pipe to save money upfront, risking premature failure and expensive maintenance down the line.

- Value Engineering: This involves analysing the entire plumbing system. Could a different layout reduce the total length of piping needed? Is there an alternative, more durable material that offers a better long-term return on investment, even if it costs a bit more initially?

This is where a knowledgeable building materials distributor becomes an invaluable partner. A strategic supplier in Dubai, like Yasu Trading, can do more than just fill an order; they can propose alternative, fully compliant products that deliver superior lifecycle value. This elevates procurement from a simple transaction to a powerful strategic advantage, protecting the project's integrity for years to come.

Why is value engineering essential for UAE projects?

Value engineering is essential in the UAE because of the region's ambitious giga-projects and landmark architecture where budgets are huge, but so is the pressure to maximise ROI. In a place like the United Arab Emirates, where the skyline is constantly being redefined, value engineering acts as the critical link between a grand vision and a financially sound reality. It helps teams navigate volatile material prices and aggressive deadlines by finding smarter, more resourceful solutions that perform for decades.

Think about the unique hurdles here: material prices can swing wildly, and project deadlines are always aggressive. Value engineering gives teams a structured way to tackle these issues head-on. It pushes everyone to think beyond the "way it's always been done" and find smarter, more resourceful solutions that don't just look good on opening day but perform for decades to come.

What’s really driving the push for VE in the UAE?

At its heart, the biggest driver for value engineering in the UAE is the relentless pursuit of cost optimisation without sacrificing the world-class quality the region is known for. With development happening at such a massive scale, getting a firm grip on spending while boosting the long-term worth of the asset is non-negotiable for developers, whether they're government-backed or in the private sector.

But the real wins go way beyond the initial project budget. By zeroing in on function and how things will perform over their entire lifecycle, value engineering helps create buildings and infrastructure that are more durable, efficient, and sustainable. It’s a proactive approach to cost management that keeps projects profitable and competitive.

Let's put this into perspective. In the UAE's supercharged construction scene, VE has become an indispensable tool for mega-projects. Consider that in one recent year, project awards in the UAE shot up by an incredible 232% over the previous year. That kind of growth screams for smart cost-control. Within a Middle East civil engineering market valued at $205 billion, well-run value engineering workshops consistently deliver significant savings, especially when they're held early in the design phase. You can find more details on how organisations like the USACE Middle East District is setting new standards with value engineering.

How does VE actually improve project quality?

Value engineering improves quality by shifting the focus from "what's cheapest?" to "what offers the best overall value?". The process puts every single component under the microscope to ensure it performs its function optimally over its entire lifespan. It forces teams to consider durability, maintenance costs, and operational efficiency right from the project's start.

Here’s a classic example. A VE study for a new coastal development in Dubai might recommend using a slightly more expensive, corrosion-resistant pipe.

- Initial Cost: Yes, the upfront price is a bit higher.

- Long-Term Value: But that pipe won't rust out and fail from the saltwater air, which saves a fortune in future repair costs and avoids disruptive shutdowns.

- Outcome: The project's overall quality and reliability get a massive boost, delivering a much better return on investment over time.

This kind of forward-thinking stops teams from falling into the trap of "value-subtracting," where chasing small, short-term savings ends up creating huge long-term headaches and expenses.

A core belief in value engineering is that true value is found in the sweet spot between cost, quality, and performance. Hacking away at one to serve another isn't value creation—it's just cost-cutting. The real goal is to lift all three at the same time.

Does value engineering help with sustainability?

Absolutely, value engineering is a powerful tool for sustainability and meeting Dubai's progressive green building codes and the wider UAE construction standards. The VE process naturally aligns with green practices because it focuses on resource efficiency and full lifecycle thinking.

When a VE team analyses a project's functions, they almost always uncover opportunities to shrink its environmental footprint. This might mean specifying materials with lower embodied carbon, designing systems that sip energy and water, or planning site logistics to slash waste. An experienced building materials distributor can be a huge help here, recommending new, eco-friendly products that still hit all the performance targets. This makes value engineering a fantastic tool for building projects that are not just cost-effective, but also responsible.

What are the phases of a value engineering workshop?

A value engineering workshop is a structured, multi-phase deep dive designed to systematically find and evaluate better ways to deliver a project. It typically involves six core phases: Information Gathering, Functional Analysis, Creative Brainstorming, Critical Evaluation, Detailed Development, and Presentation/Follow-up. This methodical process separates true value engineering from simple cost-cutting, serving as an engine for innovation.

Think of it as a strategic expedition. You bring together a diverse team of experts—architects, engineers, contractors, and even a sharp supplier in Dubai—all looking at the same map with one shared goal. Each leg of this journey builds on the last, taking you from broad ideas to concrete, actionable proposals for your value engineering in construction projects.

Phase 1: The Information Gathering Phase

Before you can improve anything, you need to understand it inside and out. The goal of this first phase is to get everyone on the same page, building a solid foundation of knowledge about the project's scope, design intent, constraints, and costs.

This is where the team gets its hands dirty, digging into the project's DNA. They’ll pore over all the essential documents:

- Architectural and engineering drawings

- Project specifications and requirements

- Detailed cost estimates and budgets

- Project schedules and timelines

- Relevant UAE construction standards and local regulations

By soaking up this information, the team ensures every discussion that follows is grounded in fact, not guesswork. A firm grasp of the project's background is also essential for a proper risk analysis, a topic we explore in our guide to construction risk management.

Phase 2: The Functional Analysis Phase

With a complete picture of the project in mind, the team moves to what many consider the heart of value engineering: functional analysis. Here, the focus shifts from what is being built to why it’s being built.

The team breaks down the project into its core components and systems, defining the primary purpose of each one using a simple verb-noun pair. For instance, a beam’s function is to "support load," and a window's is to "admit light." This simple exercise is incredibly powerful because it forces everyone to think about performance, not just physical objects. By then assigning a cost to each function, the team can quickly pinpoint high-cost, low-value areas that are ripe for improvement.

Phase 3: The Creative Brainstorming Phase

Now, the brainstorming begins. Armed with a clear understanding of the project's essential functions and their costs, the team dives into the creative phase to generate as many alternative solutions as possible.

The key here is to foster open-minded, out-of-the-box thinking without shooting ideas down prematurely. The facilitator might prompt the group with questions like, "How else can we 'support load'?" or "What other materials can 'provide enclosure'?" The ideas can be anything from simple material substitutions to complete system redesigns.

A successful creative phase isn't a free-for-all. It's a guided exploration of possibilities, focused squarely on achieving the project's essential functions through different, more valuable means.

For a project in Dubai, this could mean exploring HVAC systems better suited to the climate or proposing a plumbing layout that uses less material and labour. A knowledgeable building materials distributor can be invaluable here, suggesting new products that offer better long-term performance.

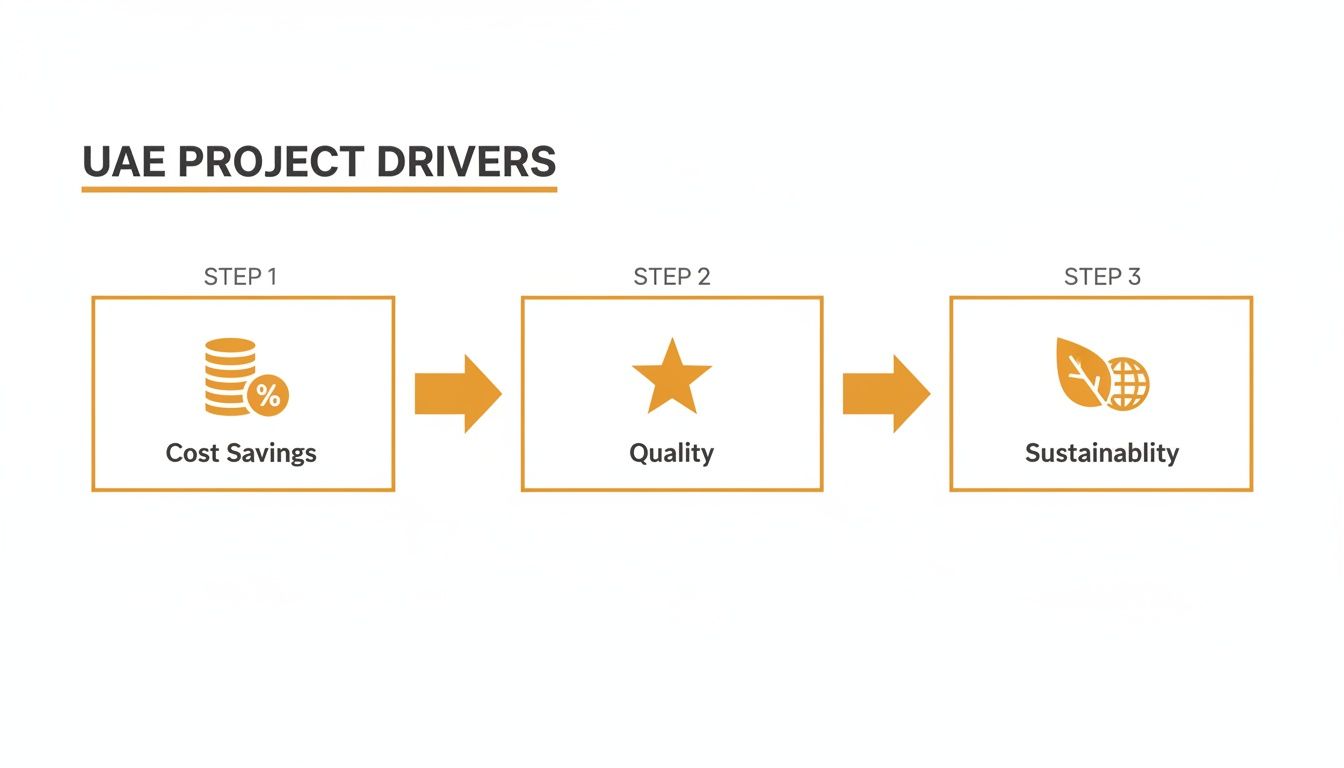

The drivers guiding this process in the UAE context are often a balance of cost, quality, and sustainability, as illustrated below.

This visual shows how successful projects balance initial savings with long-term quality and sustainability—a core tenet of the VE methodology.

Phase 4: The Critical Evaluation Phase

Once the creative storm subsides, the team switches gears to a more analytical mindset. The evaluation phase is all about systematically reviewing, ranking, and shortlisting the ideas from the brainstorming session.

The team assesses each idea against a set of clear criteria, such as potential cost savings, impact on quality, ease of implementation, and alignment with the project’s main goals. Ideas are often sorted into categories like "high potential," "needs more research," or "not feasible." This structured filtering ensures only the most practical and promising alternatives make it to the next stage.

Phase 5: The Detailed Development Phase

In the development phase, the shortlisted ideas are transformed from abstract concepts into well-defined proposals. This is where the real work begins to make these ideas tangible.

For each high-potential idea, the team develops a comprehensive plan that includes:

- Technical Descriptions: A clear explanation of the proposed change.

- Cost Analysis: A detailed breakdown of initial costs versus lifecycle savings.

- Sketches and Diagrams: Visuals to help illustrate the new concept.

- Implementation Plan: An outline of how the change would be integrated into the project.

This phase demands rigour to ensure every proposal is viable, accurately costed, and presents a compelling business case.

Phase 6: The Presentation and Follow-Up Phase

Finally, the polished VE proposals are presented to the project stakeholders and decision-makers. This presentation clearly lays out the recommended changes, the logic behind them, and the expected benefits in terms of cost, quality, and performance.

A strong presentation secures buy-in from the client and project leadership. Once approved, the proposals are formally written into the project plans. A follow-up process is then put in place to track implementation and make sure the projected savings and value improvements actually materialise.

The entire workshop is a journey, and this table summarises the key activities at each stop along the way.

Key Activities in Each Phase of a VE Workshop

| VE Phase | Objective | Example Activity |

|---|---|---|

| 1. Information Gathering | Build a shared, fact-based understanding of the project. | Reviewing all project drawings, specifications, and cost breakdowns. |

| 2. Functional Analysis | Define the purpose and cost of each project component. | Creating a verb-noun function list (e.g., "support load," "admit light"). |

| 3. Creative Brainstorming | Generate a wide range of alternative solutions. | Group brainstorming on different materials or systems to achieve a function. |

| 4. Critical Evaluation | Filter and rank ideas based on predefined criteria. | Scoring each idea against its potential savings, risk, and feasibility. |

| 5. Detailed Development | Flesh out the best ideas into fully formed proposals. | Developing cost-benefit analyses and implementation plans for top ideas. |

| 6. Presentation & Follow-Up | Secure stakeholder approval and track implementation. | Presenting the final report to decision-makers and monitoring progress. |

Each phase is crucial, guiding the team logically from a deep understanding of the project to the final presentation of vetted, high-value improvements.

How do you apply value engineering on a Dubai construction site?

To apply value engineering on-site in Dubai, you must ensure seamless collaboration and smart procurement among architects, engineers, contractors, and suppliers. Success depends on transforming approved VE ideas into reality without project delays. This shifts procurement from a simple purchasing task into a strategic advantage, where a proactive plan guided by a savvy supplier in Dubai can unlock major savings and performance boosts on the ground.

The true test of value engineering isn't in a meeting room—it's in the dust and noise of the construction site. A brilliant VE concept is worthless if it can't be executed well, and that execution hinges on the synergy between the project team and its suppliers.

Making this happen requires constant, clear communication and a willingness to adapt. It’s about ensuring every value-driven decision translates directly into a better, more efficient final building.

What is the supplier's role in on-site VE?

A strategic supplier in Dubai acts as an extension of your value engineering team, not just a delivery service. A knowledgeable building materials distributor like Yasu Trading Co. can propose cost-effective alternatives that meet or exceed original project specifications, helping to implement VE decisions directly on-site. They become your eyes and ears in the market.

Think about it this way: the project's design might call for a specific, well-known brand of plumbing fitting. A well-connected supplier can step in and:

- Suggest Alternatives: They might know of a different, fully certified fitting that offers the same (or better) durability at a lower cost.

- Confirm Compliance: They'll make sure any alternative they propose meets every single UAE construction standard and DEWA regulation, so there are no surprises later.

- Back It Up with Data: They can provide technical spec sheets and lifecycle cost analyses to give you solid evidence for making the switch.

This kind of partnership turns procurement from a reactive chore into a proactive tool for creating value, directly boosting the project’s bottom line.

How do you make VE changes without causing project delays?

You can avoid delays by tackling potential VE changes quickly through transparent communication and fast analysis, with your key supplier in Dubai involved early. When a VE opportunity arises, the supplier provides instant feedback on stock, lead times, and pricing for alternatives. This immediate information flow allows the project manager to make an informed decision without holding up the construction schedule. When collaboration starts early and stays constant, value engineering becomes a project accelerator, not a roadblock.

Where are the best on-site VE opportunities?

The best on-site VE opportunities are in components with high lifecycle costs or where technology has advanced, such as plumbing, HVAC, electrical, and safety systems. These areas allow for significant savings and performance upgrades. A trusted building materials distributor can help identify smarter, more efficient solutions that provide lasting value.

- Plumbing and HVAC Systems: Choosing PPR pipes with superior thermal insulation can cut long-term energy bills for hot water systems. In a similar vein, selecting modern, water-saving fixtures can lead to huge operational savings in commercial buildings, which aligns perfectly with Dubai's sustainability targets.

- Electrical Fixtures: Making the switch to high-efficiency LED lighting and smart control systems can dramatically slash a building's energy consumption. A good supplier can lay out a range of options, helping you balance the initial cost with long-term performance and maintenance.

- Safety Equipment: Here, value isn't just about the initial price tag. It’s about durability and compliance. Investing in higher-quality, certified safety gear means replacing it less often and, more importantly, keeping workers safe. This helps prevent costly accidents and the project delays they cause.

Working through these categories with a trusted building materials distributor can uncover some serious savings and performance upgrades. To go deeper, you can learn more about optimising your sourcing by reading a comprehensive guide on building materials. By zeroing in on these key areas, project teams can make changes that deliver real, lasting value.

What are the biggest myths about value engineering?

Several persistent myths portray value engineering as a risk rather than a strategic tool, causing hesitation among project owners and contractors. These misconceptions often frame VE as a race to the bottom that compromises quality. In reality, a well-executed value engineering process strengthens a project by boosting long-term performance and ensuring every dirham is spent with purpose. Let’s tackle these myths one by one.

"Isn't value engineering just a nicer way to say cost-cutting?"

No, this is the most damaging myth; true value engineering is fundamentally different from simple cost-cutting. VE focuses on improving value by analysing function, not just reducing the initial price by selecting cheaper, lower-quality materials. Cost-cutting is reactive, asking, "How do we make this cheaper?" while VE is proactive, asking, "Is there a better, more efficient way to achieve this function?".

Think of it this way: cost-cutting is reactive. It asks, "How do we make this cheaper?" Value engineering is proactive. It asks, "Is there a better, more efficient way to get this done?" For example, a cost-cutting mindset might just swap out the specified plumbing fixtures for a budget version. A VE team, on the other hand, might rethink the entire plumbing layout to use less pipe, cutting down on both materials and labour while keeping the system working just as well, if not better.

The formula for value is simple: Function divided by Cost (Value = Function / Cost). The whole point of VE is to make that ratio better. You either boost the function for the same money or keep the function and lower the cost. You never, ever sacrifice the essential function just to save a few dirhams.

This difference is absolutely critical, especially when you're working within the strict UAE construction standards.

"Does VE mean we have to give up on quality and the original design?"

Not at all; in fact, a core principle of value engineering is to maintain or even improve quality while honouring the architect's original vision. The process respects a project's aesthetic and performance goals rather than watering down the design. VE often focuses on unseen components, like finding a more efficient HVAC system or better wall insulation, ensuring the target is met in a smarter way. An experienced building materials distributor can suggest alternative materials that fit the design brief perfectly while offering superior long-term value.

"Is it too late for VE if construction has already started?"

No, it is never too late for value engineering, although its greatest impact is in the early design phases. Even after construction has started, VE can deliver significant savings by focusing on construction methods, logistics, and procurement. On-site, VE can identify opportunities for faster-curing materials or prefabricated components to save time and labour.

For instance, your supplier in Dubai might tip you off about a new, faster-curing concrete mix that could shave weeks off the schedule, saving a significant amount on labour and financing costs. In the UAE, VE is also crucial in public-private partnerships, where it’s used to explore different options and secure major cost reductions. It also helps the industry tackle big challenges like labour shortages—a problem affecting 56% of firms—by promoting things like prefabrication that reduce the need for manual work on site.

If you'd like to dive deeper, you can read more about VE's impact on UAE construction dynamics and cost management to see how it ensures projects deliver genuine value, not just cheap upfront costs.

How does value engineering work in practice?

Value engineering works by turning abstract ideas into tangible savings and improved performance, which is especially critical in a fast-moving market like the UAE. Its effectiveness is often seen in simple, intelligent changes that create a ripple effect of value. A practical example is a luxury hotel renovation in Dubai where the original high-end plumbing fittings are swapped for a stylish, water-saving alternative proposed by an experienced supplier in Dubai, cutting initial costs and long-term utility bills.

Let's walk through that practical example again. Picture a luxury hotel renovation taking place right in the heart of Dubai. The original blueprints call for high-end chrome plumbing fittings from a famous European brand—the default choice for prestige projects.

However, during a value engineering review, an experienced supplier in Dubai steps in. They propose an alternative set of fittings. These aren't just a cheaper knock-off; they are equally stylish and just as durable, but with one key difference: they incorporate advanced water-saving technology. This single move doesn't just cut the initial procurement cost. It also sets the hotel up to slash its water and energy bills for the long haul, delivering a much stronger return on investment.

Where can strategic product selection make the biggest impact?

Strategic product selection can unlock enormous value in systems with high operational or maintenance costs, such as HVAC, electrical, and plumbing networks. Choosing more efficient or durable materials in these areas has a direct and lasting impact on a building's lifecycle expenses. This is where a proactive building materials distributor can provide significant input.

Take a new commercial tower, for instance. The initial electrical plan specifies a standard wiring setup. But a VE analysis, brought to the table by a proactive building materials distributor, suggests a smarter layout using higher-grade, more conductive wiring. While it might sound like a minor tweak, this adjustment saves kilometres of cable, cuts down on installation labour, and ultimately lowers the building's day-to-day energy consumption. It’s a clear win for the construction budget and the future tenants.

Value engineering shines brightest when it uncovers an alternative that is not just cheaper, but smarter. It's about finding that sweet spot where cost-efficiency, long-term performance, and strict compliance with UAE construction standards all meet.

How does value engineering address regional challenges in the UAE?

In the Gulf, value engineering is a direct response to regional challenges like rising material costs and ambitious sustainability goals. With the GCC's massive $3.1 trillion project pipeline, VE provides a proven method for delivering significant savings and reducing lifecycle costs. This data-driven approach is why a reliable, forward-thinking supplier is crucial for project success in the UAE.

It’s no surprise, then, that a recent survey of professionals in the region found that 69% champion the use of VE on medium to large projects. Why? Because it has a proven track record of delivering significant savings and trimming down lifecycle costs. This data-driven approach is exactly why having a reliable, forward-thinking supplier is so crucial for successful project delivery in the UAE. You can find more details on this in the MENA economic and construction outlook on AECOM's website.

Still Have Questions About Value Engineering?

We get it. Value engineering is a powerful tool, but it often comes with a few common questions from project managers and developers here in the UAE. Let's clear up some of the most frequent ones.

When is the best time to bring in value engineering?

The best time to implement value engineering is as early as possible, ideally during the conceptual or schematic design phase. Getting in early provides the most leverage to influence the design, budget, and schedule without causing expensive redesigns later. That said, VE can still deliver significant savings at any stage, even during construction, by focusing on procurement and material choices.

Does value engineering mean we have to sacrifice quality?

Not at all; this is the biggest misconception about value engineering. When done correctly, VE protects and often enhances quality. The goal is not to find the cheapest option but to analyze a component's function to find a better, smarter, or more efficient way to achieve the same or better result, all while respecting UAE construction regulations.

Think of it this way: VE is about finding a more scenic and efficient route to your destination. It's not about picking a lesser destination. The goal is always to increase value, and quality is a massive part of that equation.

How does a building materials supplier fit into this?

A good supplier in Dubai is a key partner in the value engineering process, acting as an extension of your project team. As a long-standing building materials distributor, we help by suggesting cost-effective, high-performance product alternatives, providing the technical data needed for confident decision-making, ensuring compliance with local codes, and delivering quick cost comparisons to keep the project on schedule.

Is this just for huge, new construction projects?

Absolutely not; value engineering principles scale perfectly and are just as effective for smaller builds and renovations as they are for massive developments. On a refurbishment job, for instance, VE can pinpoint opportunities to upgrade to modern, energy-efficient materials, tweak layouts for improved flow, and slash long-term running costs. It delivers fantastic value, no matter the project's size.

Ready to unlock the full potential of your next project? Yasu Trading Co. LLC provides the expert guidance and high-value building materials you need to make your value engineering goals a reality. See what we offer at https://yasutrading.com.