Choosing the Right Wood Adhesive Glue for UAE Construction

Choosing the right wood adhesive glue isn't just a simple matter of sticking wood together. Here in the UAE, it's about guaranteeing structural integrity and long-term durability, especially with our unique climate. This guide is specifically for contractors and project managers in Dubai who need to make smart, informed decisions that meet demanding local standards. We're cutting through the generic advice to get straight to the real-world challenges of heat and humidity.

Navigating Wood Adhesives in Demanding Climates

In the fast-paced construction world of the UAE, your choice of wood adhesive glue is a critical decision. It directly impacts a project’s strength, finish, and compliance. Whether you're working on a towering skyscraper or a detailed interior fit-out, the adhesive's performance under intense heat and shifting humidity is non-negotiable. A bond that gives way can trigger costly rework, throw schedules into chaos, and create serious structural safety risks.

This guide is all about practical, on-the-ground insights for professionals. We'll walk through the main adhesive families, from the versatile PVAs perfect for interior joinery to the seriously tough polyurethanes built for waterproof applications. The whole point is to give you the confidence to select the right product from a building materials distributor for any job that comes your way.

Why does your adhesive choice matter in the UAE?

Getting the nuances of different glues right is crucial for a successful project. The wood adhesive market in the United Arab Emirates is a major part of the wider Middle East's growth story. As a construction hub, the UAE relies heavily on quality wood adhesives for everything from new builds to maintaining existing structures in the woodworking industry.

Here are the key things you absolutely have to consider for any UAE project:

- Heat Resistance: The adhesive must hold its bond strength without softening or failing when temperatures soar.

- Humidity Tolerance: High ambient moisture, especially in coastal cities like Dubai, can mess with how glues cure and their stability over time.

- Compliance: Every product has to meet strict UAE construction standards to get project approval and ensure safety.

- Application Speed: Open times and clamp times need to work with your project's fast-paced schedule to keep things moving efficiently.

When you're building with wood in tough environments, knowing your adhesives is key to long-term success. This knowledge even extends to specialised products like deck joist tape, which is vital for protecting structural components from moisture damage.

By mastering these factors, you can make sure every joint, laminate, and finish doesn't just look good, but is engineered to last. The right product from a supplier in Dubai is a direct investment in the quality of your work, protecting your reputation and keeping clients happy.

What are the main types of wood adhesives?

Choosing the right wood adhesive glue is a lot like picking the right tool for the job. You wouldn't use a sledgehammer to hang a picture frame, right? It's the same with glues. Using the wrong one leads to weak joints, failed projects, and a lot of frustration.

When you get down to it, there are four main families of adhesives that you'll see on almost every project site in the UAE, from high-rise interiors in Dubai to custom villas in Abu Dhabi. Each has its own personality, strengths, and weaknesses. We’ll look at the classic workhorse, Polyvinyl Acetate (PVA), the waterproof powerhouse, Polyurethane (PU), the structural problem-solver, Epoxy, and the quick-fix specialist, Cyanoacrylate (CA). Let's break down what makes each one tick so you can talk to your supplier in Dubai with confidence.

Polyvinyl Acetate (PVA) Glue

This is the one everyone knows. PVA is what most people mean when they say "wood glue." It’s the reliable, go-to adhesive for a huge range of interior carpentry, joinery, and furniture making. It works by soaking into the wood fibres and forming a bond as its water base evaporates. Simple and effective.

You’ll find PVA in almost every workshop because it's non-toxic, cleans up easily with water, and creates a bond that’s often stronger than the wood itself. The catch? Its biggest weakness is water. Standard PVA is not meant for outdoor use or damp areas unless you get a specifically formulated water-resistant version (like a Type II).

Polyurethane (PU) Glue

When the job needs to stand up to the elements, you bring in polyurethane. Think of it as the all-weather specialist. PU glue is moisture-cured, which is a fancy way of saying it uses moisture from the air and the wood to kickstart a chemical reaction. The result is a 100% waterproof bond that’s incredibly tough.

This makes it the clear winner for outdoor furniture, boat repairs, exterior doors, and any other project that will face rain or the UAE’s high humidity. PU glue also has a neat trick up its sleeve: it expands a little as it cures. This foaming action helps fill small, imperfect gaps in a joint. Plus, it’s great for bonding wood to other materials like metal, stone, or plastic, which is a huge advantage on a busy construction site.

Key Takeaway: For any exterior woodwork or areas with high moisture exposure in the UAE, polyurethane is often the superior choice. Its waterproof nature ensures the joint remains stable despite humidity, making it a reliable performer that meets high UAE construction standards for durability.

Two-Part Epoxy

Epoxy is the structural engineer of the adhesive world. It comes in two parts—a resin and a hardener. When you mix them, a chemical reaction starts that creates an unbelievably strong, rigid, and gap-filling bond. If you need maximum strength, this is what you reach for.

It's the ultimate problem-solver for structural repairs, filling large voids, or recreating missing pieces of wood. Unlike PVA glues, epoxies don’t shrink as they cure, so they’re perfect for stabilizing joints that aren't perfectly tight. Their brute strength is why they’re specified for load-bearing joints and critical repairs.

- Ideal for Structural Repairs: Strong enough to rebuild missing sections of wood.

- Superior Gap-Filling: Cures into a hard, non-shrinking solid.

- Excellent Water and Chemical Resistance: Creates a tough, impermeable bond.

- Longer Working Time: Gives you more time to get complex assemblies just right before it sets.

Cyanoacrylate (CA) Glue

You probably know this one as super glue. CA is the instant-gratification adhesive. It’s all about speed. Curing in just a few seconds, it’s perfect for tacking small trim pieces in place, making quick repairs on-site, or holding a part steady while a stronger, slower-curing glue like epoxy does its work.

While it’s incredibly fast, the bond can be a bit brittle. It's not designed for large structural joints that need to handle serious stress. Think of it as a third hand for finishing work where you need speed and precision. When you're stocking up, any good building materials distributor will offer different thicknesses (viscosities) of CA glue for different tasks.

To make things even clearer, let's put these four glues side-by-side.

Comparing Common Wood Adhesive Glues

Here's a quick cheat sheet to help you see at a glance which glue is best suited for your next task. Think of it as a quick reference guide for comparing the main players in the world of wood adhesives.

| Adhesive Type | Key Feature | Common UAE Application | Water Resistance |

|---|---|---|---|

| PVA Wood Glue | Easy to use, strong bond, water cleanup | Interior furniture, cabinetry, general joinery, trim work | Low to Medium |

| Polyurethane (PU) | 100% waterproof, expands to fill gaps | Outdoor furniture, decks, boat building, exterior doors | Excellent |

| Two-Part Epoxy | Maximum strength, superior gap-filling | Structural repairs, filling voids, bonding dissimilar materials | Excellent |

| Cyanoacrylate (CA) | Extremely fast curing (seconds) | Quick fixes, attaching small mouldings, temporary holds | Low |

Each of these adhesives has a definite place in a professional's toolkit. Matching the glue's properties to the project's demands is the first step toward building something that not only looks great but is built to last.

How do you match the right glue to the job?

Picking the right wood adhesive isn't just about grabbing a bottle off the shelf. It’s a calculated decision that weighs the wood you’re using, where the finished piece will live, and the kind of stress it will face. Get it wrong, and you’re looking at weak joints and expensive callbacks—a headache no contractor in Dubai needs. The real goal is to find the perfect adhesive that won’t let you down.

It all starts with a simple question: what does this job demand? Are you building a structural beam that has to carry a serious load? Or maybe some delicate interior trim that just needs to look perfect? What about an outdoor piece that will bake in the harsh UAE sun? Each job has its own unique needs, and there's a specific glue that's right for it.

What is the best adhesive for structural work?

For heavy hitters like laminated beams, load-bearing joints, and other critical assemblies, you can't compromise. Structural-grade epoxies are essential for meeting strict UAE construction standards because they create incredibly strong and rigid bonds, and they excel at filling gaps without shrinking to maintain integrity.

Of course, the wood itself plays a part. Oily hardwoods, for example, can be tricky and might need some special prep work before glue-up. Digging into the details of choosing the right hardwood for longevity and style can save you a lot of trouble down the line. Nailing the epoxy choice with your building materials distributor ensures you get a bond that’s built for the long haul.

Which adhesive is best for aesthetic and finishing work?

For projects where looks are everything, like fine furniture or veneers, your priorities shift to clean, invisible bonds. This is where Polyvinyl Acetate (PVA) glues shine, offering a strong bond and easy water-based cleanup. For tiny trim pieces, Cyanoacrylate (CA) glue is a great tool, setting almost instantly to speed up your workflow.

The trick is to pick a wood adhesive glue with the right clamp time. You want something that lets you work efficiently without cutting corners on the quality of the bond, giving you that flawless, professional finish.

Which glue should be used for exterior projects?

For exterior projects in Dubai, the adhesive must be completely waterproof and able to handle intense heat and humidity. Your standard interior glue will fail quickly. Polyurethane (PU) adhesives are a fantastic choice, being 100% waterproof, while a Type I water-resistant PVA, specifically rated for outdoor use, is another solid option. Sourcing a truly waterproof adhesive from a trusted supplier in Dubai isn’t just recommended—it’s non-negotiable.

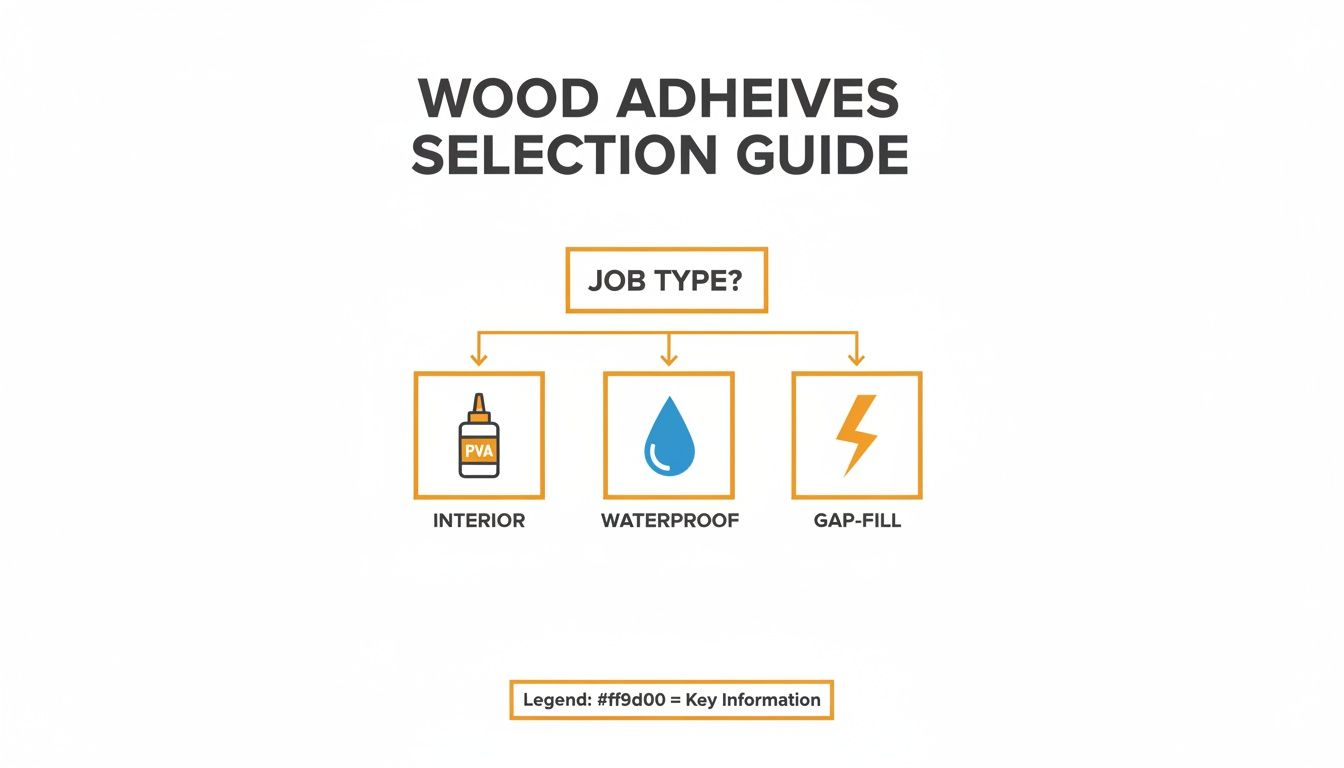

This flowchart gives you a quick visual guide to help you make the right call.

As you can see, it all boils down to the core need of your project. Whether it’s for inside, outside, or filling gaps, knowing your primary goal is the first step to choosing the right adhesive.

Practical Application Scenarios

Let's walk through a few real-world examples that UAE contractors face all the time.

Scenario 1: Building Hotel Furniture For high-end hotel furniture, you'll likely use a tag-team approach. A quality PVA glue is your workhorse for the main joinery, giving you that core strength. Then, a fast-setting CA glue is perfect for quickly tacking on decorative trim, which really helps speed up assembly.

Scenario 2: Bonding Outdoor Decking When you're putting down decking that’s going to be blasted by sun and rain, a polyurethane adhesive is the way to go. Its waterproof nature and flexibility mean the bond won't crack or fail as the wood expands and contracts in the heat.

Scenario 3: Structural Beam Repair Got a crack or a void in a laminated wooden beam? This is a job for two-part epoxy, no question about it. Its ability to fill gaps while providing incredible strength will bring that beam back to full integrity, keeping it safe and compliant with UAE construction standards.

By thinking through what each job really needs, you can confidently source the perfect wood adhesive glue every time. It’s how you ensure every project is built to last and finished to the highest possible standard.

Understanding Key Adhesive Performance Metrics

To really get the measure of a wood adhesive glue, you have to speak its language. That technical data sheet that comes with every bottle isn't just fine print; it's the playbook telling you exactly how that adhesive will perform on your job site.

Once you know what to look for, it completely changes how you source materials. Instead of just taking a recommendation at face value, you can look any building materials distributor in the eye and assess their products with confidence, ensuring they meet your project’s demands and line up with UAE construction standards. It’s about making a strategic choice, not just a purchase.

The global wood adhesives market, valued at a massive figure and projected to hit USD 16.68 billion by 2033, shows just how critical this precision is. That growth is being fuelled by the very work we do every day.

What is adhesive open time and clamp time?

Open time is your working window after applying glue but before joining the pieces, while clamp time is the minimum period the joint must be held under pressure. A longer open time is crucial for complex assemblies, giving you time to align everything perfectly. Clamp time is a non-negotiable waiting period to ensure the bond builds sufficient strength to hold itself together.

It’s a classic rookie mistake to mix these two up. Open time is for assembly, clamp time is for curing. Rush either one, and you’re practically guaranteeing joint failure, which means costly rework and frustrating delays.

How is adhesive bond strength measured?

Adhesive bond strength is measured in pounds per square inch (psi) or megapascals (MPa) and indicates how much force a joint can withstand. For most woodworking, a bond strength stronger than the wood itself—typically around 1,800 to 2,500 psi—is desired. When the bond is stronger than the wood, it means the wood fibres will tear before the glue line fails under extreme stress, indicating a perfect bond. When checking specs from a supplier in Dubai, look for a strength rating of 3,000 psi or higher to ensure the adhesive is never the weakest link.

As the industry evolves, it's also worth looking at how performance and sustainability are coming together. You can learn more about sustainable adhesives and sealants for green construction and see what the future holds.

Why do water and heat resistance ratings matter?

In the UAE's intense climate, water and heat resistance are essential for durability. Adhesives are often rated using the American National Standards Institute (ANSI) system. A Type I rating signifies a waterproof bond suitable for outdoor use, while a Type II rating indicates water resistance for occasionally damp indoor areas like kitchens. Using a Type II adhesive for an outdoor pergola in Dubai is a recipe for disaster. The combination of humidity and relentless sun will break that bond down in no time. Always, always match the resistance rating to the real-world conditions the project will face.

Mastering Application for a Flawless Bond

You can have the best wood adhesive in the world, but it’s not going to do you any good if it’s applied poorly. Getting the application process right is what separates a joint that will outlast the project from one that fails under the first sign of stress. This is doubly true on a busy UAE construction site, where heat, dust, and humidity are always part of the job.

For any trade professional, mastering these field-tested techniques is non-negotiable. From the detailed work of surface prep to the finer points of clamping pressure, every single step counts. Let's walk through the on-the-ground advice for getting a perfect bond, every time.

Why is surface preparation so important?

Surface preparation is the foundation for a strong bond because it ensures the adhesive makes full contact with the wood fibres. On a dusty Dubai construction site, a thin layer of sawdust, oil, or moisture can act as a barrier, preventing the wood adhesive glue from properly penetrating the wood and guaranteeing a weak bond.

For a bond to achieve its maximum rated strength, the wood surfaces must be pristine. Taking an extra minute to wipe down surfaces with a clean cloth or a tack rag is one of the highest-return activities you can perform on site.

How much glue should you apply?

You should apply a thin, even coat that covers the entire surface, aiming for just enough glue to create a small, consistent bead of "squeeze-out" along the joint line once clamped. Applying too little glue creates a "starved" joint with weak spots, while applying too much creates a wasteful mess that is difficult to clean. For specialised work, you'll find plenty of details in our complete guide to selecting the right paints and finishes for wood, which often demands the same level of prep work.

What is the role of clamping pressure?

Clamping brings wood surfaces into tight contact, spreading the adhesive evenly and forcing it deep into the grain to create a strong, thin glue line. The goal is to apply firm, consistent pressure across the entire joint without overtightening, which can squeeze out too much glue and weaken the bond. Using enough clamps and spacing them evenly is crucial for a bond that will meet demanding UAE construction standards.

How do temperature and humidity affect curing?

In the UAE, high heat can reduce an adhesive's open time, while high humidity can significantly extend the curing time for water-based glues like PVAs. As a professional, you must account for your working environment, potentially leaving pieces clamped for longer on an open-air site to ensure the wood adhesive glue reaches its full design strength. Always check the product data sheet from your building materials distributor for specific environmental limits.

Your Top Questions About Wood Adhesives Answered

Working with wood adhesives in the UAE throws a few curveballs you won't find elsewhere. The heat, the humidity—it all changes the game. Here, we tackle the most common questions we hear from contractors on the ground, with straightforward answers to keep your projects on track and up to standard.

What is the best wood adhesive glue for outdoor use in Dubai's climate?

For outdoor projects in Dubai's climate, the best adhesive is one that is both fully waterproof and resistant to heat and UV rays. Your top choice is Polyurethane (PU) glue, which is 100% waterproof and cures using ambient moisture. Another excellent option is a Type I PVA glue, specifically engineered for exterior use and capable of withstanding extreme temperature fluctuations. Always verify a waterproof or exterior rating on the technical data sheet from your building materials distributor.

How does high humidity affect glue curing times in the UAE?

High humidity in the UAE has opposite effects on different glues, impacting project timelines. For water-based PVAs, it slows down water evaporation, requiring longer clamp times to ensure a strong joint. Conversely, for moisture-curing glues like polyurethane, high humidity speeds up the curing reaction, significantly reducing your available working time before the glue sets.

Can I use wood glue to fill gaps between wood?

No, you should not use standard wood glue to fill structural gaps, as it shrinks and creates a weak, brittle spot. For strong, gap-filling repairs, a two-part epoxy is the correct choice because it cures into a rock-solid, non-shrinking solid. While mixing sawdust with PVA might work for minor cosmetic fixes, any load-bearing application requires a proper gap-filling adhesive from a trusted supplier in Dubai.

What is the shelf life of wood glue in a hot climate?

Most wood glues have a one to two-year shelf life under ideal conditions, but this can be shortened by the UAE's hot climate. To maximize shelf life, store adhesives in a cool, dry place away from direct sunlight and extreme temperatures, and always seal containers tightly. Checking the manufacturing date when purchasing from a supplier in Dubai ensures you start with a fresh, reliable product.

Is it necessary to clean squeeze-out and if so when?

Yes, cleaning squeeze-out is essential to prevent it from sealing wood pores and causing blotchy spots when finishing. For water-based PVA glues, wait 20-30 minutes for the glue to become rubbery, then scrape it off easily. For polyurethane glues, it's best to let the foamy squeeze-out cure completely before scraping or sanding it off to avoid a difficult cleanup.

How can I ensure the strongest possible bond?

To ensure the strongest possible bond that meets UAE construction standards, you must focus on three fundamentals. First, ensure pristine surface preparation by making sure wood is clean, dry, and free of contaminants. Second, apply correct, even clamping pressure without overtightening to avoid a "starved" joint. Finally, always respect the manufacturer's recommended curing times before removing clamps.

The strength of your project is only as strong as its weakest joint. Diligence in preparation and application is not just a recommendation; it is a requirement for professional-grade work that is built to last. A disciplined approach ensures that the wood itself will fail before the glue line ever does.

For over two decades, Yasu Trading Co. LLC has been the trusted partner for contractors across the UAE, supplying high-performance adhesives and a complete range of municipality-compliant building materials. Ensure your projects meet the highest standards with products sourced for our demanding climate. Explore our extensive inventory and benefit from our expert support and reliable, site-direct delivery by visiting us at https://yasutrading.com.