A Contractor's Guide to Fiber Cement Board in the UAE

On any construction site, you're constantly weighing up materials. You need something that gets the job done right, stands up to the local climate, and won't cause headaches down the line. That's where fiber cement boards come in.

At their core, these boards are a simple but incredibly effective mix: Portland cement, sand, water, and cellulose fibres. But don't let the simple recipe fool you. This isn't just a basic building panel; it's a high-performance composite engineered to be tough, versatile, and incredibly resilient.

The Go-To Building Skin for a Tough Climate

Think about building in the UAE. You’re up against intense sun, high humidity, and abrasive sandstorms. Traditional materials just don't cut it. Wood rots, gypsum turns to mush when it gets wet, and certain plastics go brittle under that relentless UV exposure. This is precisely the gap that fiber cement fills. It's built for these conditions.

The magic happens during manufacturing. A slurry of the core ingredients is mixed, pressed into sheets, and then cured in a high-pressure autoclave. This isn’t just about drying it out; the process triggers a chemical reaction that bonds everything together on a molecular level. What comes out is an exceptionally stable and robust panel.

The Secret to Its Strength

It all comes down to how the components work together. The cement brings the muscle—compressive strength, plus a natural resistance to fire and moisture. But on its own, cement is brittle. That’s where the cellulose fibres come in. They weave through the mixture, adding flexibility and tensile strength, which stops the board from cracking under pressure or from impacts.

This combination creates a material that doesn't just survive the Middle Eastern climate; it thrives in it. You end up with a building skin that delivers outstanding protection and looks good for years.

Think of a fiber cement board as a shield for your building. Its dense, tough composition stands up to the physical and environmental battering common in the region, protecting the building's integrity and appearance for decades with almost no maintenance.

A Market That's All About Performance

The switch to fiber cement isn't just something we're seeing on a few jobsites; it's a major trend across the region's construction sector. With the UAE's ambitious mega-projects demanding materials that last, the market has exploded.

The numbers tell the story. The UAE fiber cement board market jumped from USD 208.9 million in 2022 and is on track to hit USD 645.9 million by 2030. That’s a compound annual growth rate (CAGR) of 15.2%. You can dig deeper into these construction material trends over at Grand View Research.

This isn't just about a new product gaining popularity. It reflects a fundamental shift in mindset. Contractors are wisely moving away from materials that need constant repair and replacement, choosing smart solutions like fiber cement that offer better long-term performance and lower lifetime costs.

What This Means for Your UAE Projects

For finishing and MEP teams on the ground, the advantages are clear and immediate. Here’s why you’re seeing fiber cement specified more and more on projects from Dubai to Abu Dhabi:

- Stands Up to Extreme Weather: It’s dimensionally stable. That means it won’t swell, shrink, or warp with the constant swings in heat and humidity we see here.

- Seriously Fire-Resistant: Fiber cement is non-combustible. It has a high fire-resistance rating, which is critical for meeting the strict UAE Fire and Life Safety Codes for facades and internal partitions.

- Forget About Pests and Rot: Unlike anything wood-based, it's completely immune to termites, insects, and mould. That’s a massive plus in any climate.

- Low, Low Maintenance: Once it's installed and painted, you can pretty much forget about it. This saves the building owners a huge amount of time and money over the years.

When you get right down to it, fiber cement board is a reliable, high-performance solution that directly answers the biggest challenges of building in this part of the world. It’s not just another material choice; it’s an engineered solution for a demanding environment.

Selecting the Right Fiber Cement Board for Your Application

Choosing the right fiber cement board isn’t just about ticking a box on a spec sheet. It's a fundamental decision that ripples through your entire project, affecting everything from structural performance and fire safety to the final look and feel of the space. Get this wrong, and you could be looking at costly rework, performance issues, or frustrating delays.

Let's cut through the jargon and get practical. To make the right call for your UAE project, you need to get your head around three core properties: density, thickness, and edge type. Each one plays a critical role, whether you're cladding a tower exposed to coastal winds or fitting out a high-traffic hotel lobby.

Decoding Board Density

Think of board density as its toughness. It’s a straightforward measure of how much material is packed into the panel, which tells you a lot about its impact resistance, durability, and even how well it blocks sound. It’s like the difference between a hollow-core interior door and a solid-core fire door—one is light and functional, the other is built like a tank for serious protection.

Matching the density to the job is non-negotiable for long-term success.

- High-Density Boards: These are the heavy hitters. Engineered for maximum punishment, their tightly packed composition makes them the go-to choice for external cladding, walls in busy commercial spaces, and anywhere else that has to stand up to serious wear and tear.

- Medium-Density Boards: Your versatile workhorse. These boards strike a great balance between strength and workability, making them perfect for general internal partitions, ceilings, and soffits where you need solid performance without the extreme resilience of a high-density panel.

- Low-Density Boards: Lighter and easier to handle, these are designed for jobs where weight is a key consideration. Think tile backer boards in wet areas or specific ceiling systems. They aren't built for high-impact zones, but they offer excellent moisture resistance in a much more manageable format.

Matching Thickness to Performance Needs

A board's thickness is directly tied to its fire rating, acoustic performance, and structural strength. A thicker board simply puts more material between a potential fire and the structure, and it's more effective at deadening sound. This makes it a critical specification for projects like hospitals, schools, and residential towers where safety and occupant comfort are top priorities.

For instance, a 12mm board might be perfectly fine for a standard office partition. But if you’re building a fire-rated assembly, you could need an 18mm board (or even thicker) to comply with the strict UAE Fire and Life Safety Code. Always have the manufacturer's technical data sheets open and compare them against your project's specific fire and acoustic requirements.

Choosing the right specification is a process of matching the material’s inherent strengths to the demands of the environment. A high-density, thick board used for external cladding on a coastal high-rise is specified for its ability to resist wind loads, moisture, and impact—a role a low-density interior board could never fulfil.

This is exactly why, for the punishing climate we have here in the UAE, fiber cement so often comes out on top.

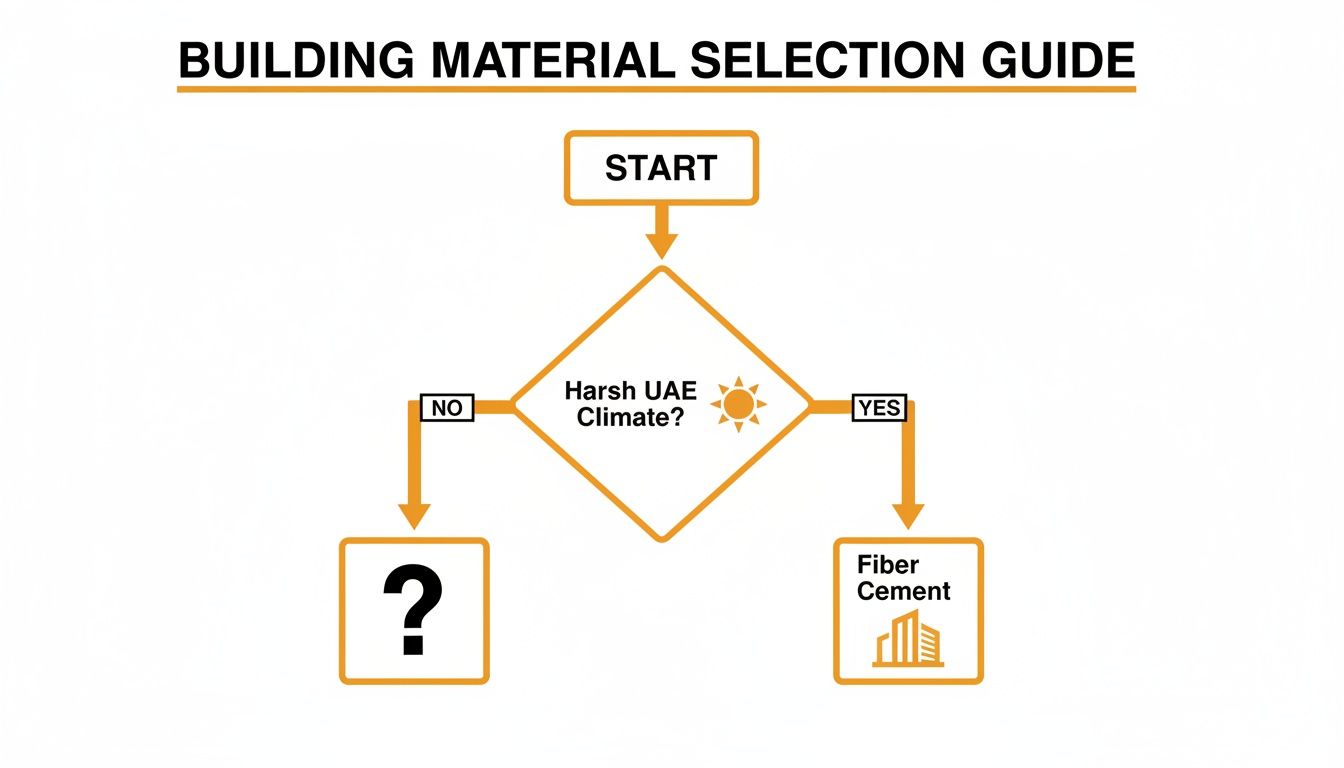

The flowchart above really simplifies that initial decision. When you need something that will last in a tough environment, fiber cement is the logical choice.

Fiber Cement Board Specification Selector

To make this even clearer, here’s a quick-glance table to help you match the board density to the application.

| Specification | High-Density Board | Medium-Density Board | Low-Density Board |

|---|---|---|---|

| Typical Density | > 1400 kg/m³ | 1200 - 1400 kg/m³ | < 1200 kg/m³ |

| Key Attribute | Maximum durability & impact resistance | Balanced strength & workability | Lightweight & easy to handle |

| Best For | External Cladding, High-Traffic Corridors, Facades | General Partitions, Ceilings, Eaves & Soffits | Tile Backer Boards, Non-Load Bearing Ceilings |

| UAE Project Example | Exterior facade of a Dubai Marina tower | Internal walls in a business hotel | Wet area wall lining in a residential villa |

This table should serve as a solid starting point, but always confirm with the manufacturer's data for your specific product.

Understanding Edge Profiles

The edge finish on a board might seem like a small detail, but it has a huge impact on installation speed and the final look. Get it wrong, and your finishing team will have a nightmare trying to achieve a clean surface.

- Square Edge: This is your standard, no-fuss profile with straight, 90-degree edges. It’s perfect for designs where the joints are meant to be seen, like in a board-and-batten style, or where you're using cover strips.

- Tapered Edge: These boards are clever—the edges get slightly thinner, creating a shallow V-groove when you butt them together. This recess is designed to be filled with jointing compound and tape, allowing finishers to create a perfectly seamless, monolithic surface.

- Tongue and Groove (T&G): Featuring an interlocking profile, T&G edges create a very strong and tight connection. This is ideal for jobs that need extra rigidity and a weather-tight seal, like flooring underlayment or certain types of interlocking cladding systems.

By getting these three details right—density, thickness, and edge profile—you're not just ordering a product. You're specifying a solution that’s built to perform in the demanding conditions of a UAE construction project, ensuring a flawless and durable result.

Core Applications in Modern UAE Construction

The real test of any building material isn’t in a brochure; it’s on the job site. In the heat and hustle of the UAE’s construction scene, fiber cement board is no longer a niche product but a go-to solution for a whole host of challenges. Its sheer versatility means you can solve multiple problems with a single, dependable panel.

We see it everywhere now, from the sleek towers of Dubai to the sprawling villa communities in Abu Dhabi. It’s not just a fancy covering; it’s a core part of modern building envelopes and interior systems. Let’s break down the four main areas where this stuff really makes a difference.

A Resilient Shield for External Cladding

Think about what a building’s facade goes through here in the UAE. It’s a constant battle against brutal sun, abrasive sandstorms, and sticky humidity. This is where fiber cement board proves its mettle, acting as a tough, non-combustible shield that keeps the building safe and looking sharp for years.

Some materials will warp, fade, or go brittle under that relentless UV exposure, but fiber cement is built different. It’s dimensionally stable, meaning it doesn’t really expand or contract with the wild temperature swings. For the installation crew, that means fewer surprises, no cracking, and an exterior that can genuinely handle the region’s climate.

Creating Quiet Spaces with Internal Partitions

Walk into any busy office or apartment block, and you’ll instantly appreciate the need for good sound insulation. This is another area where fiber cement outshines standard drywall. Its density is the key, making it a fantastic choice for internal partitions where you need to keep things quiet.

It does a great job of blocking sound from travelling between rooms, which is a massive plus for creating comfortable spaces. That’s why you’ll see it specified for:

- Corporate Offices: Keeping boardroom meetings confidential from the open-plan areas.

- Residential Towers: Cutting down on noise transfer between neighbouring apartments.

- Hospitality Projects: Giving guests the privacy they expect in hotels and resorts.

For contractors, there's a bonus: using it for partitions also adds serious impact resistance in busy corridors, which means fewer dings and scrapes to patch up later.

The versatility of fiber cement board is its greatest strength. A single material can be used to create a fire-rated, weather-resistant external facade and a sound-insulating, impact-resistant internal wall, simplifying procurement and site logistics.

The Superior Choice for Wet Areas

Kitchens, bathrooms, plant rooms—these are tough environments. They’re constantly under attack from moisture and humidity. Regular gypsum board just gives up; it soaks up water, swells, and quickly becomes a breeding ground for mould. That’s a recipe for expensive callbacks and unhappy clients.

Fiber cement board, on the other hand, is practically immune to moisture, rot, and mould. It gives you a rock-solid, stable backing for tiles and other finishes in wet areas. For the finishing teams, it’s peace of mind. You know the wall you’re working on is built to last, whether it's behind a shower, a commercial kitchen sink, or a bank of washroom facilities.

Ceilings and Soffits That Never Sag

Finally, let’s look up. For ceilings, eaves, and soffits, fiber cement has a clear edge. Its inherent strength and rigidity stop that annoying sag you sometimes see with other panels, especially over large spans or in areas with fluctuating humidity.

This stability keeps ceilings perfectly flat and architectural lines crisp, often without needing extra framing. It’s a simpler install that guarantees a high-quality finish for the life of the building. From exterior soffits getting blasted by the elements to clean-lined interior ceilings, it’s a reliable and visually sharp solution.

Mastering Installation and Finishing Techniques

The incredible durability of fiber cement board is only as good as its installation. For teams on site, getting the finish right isn't just about looks; it's about delivering the long-term performance promised in the project plans. Nailing the right techniques for handling, cutting, and fastening this material is key to avoiding common headaches, cutting down on waste, and creating something that can take on the UAE’s demanding climate.

It all starts with a methodical approach. From the initial prep work to the final sealant, every step has to be done by the book. This means giving your crew the right tools, sticking to strict safety rules, and really understanding the material you're working with. A well-planned installation prevents those costly callbacks and makes sure the building performs exactly as it was designed to.

Your Pre-Installation Checklist

Before a single board gets cut, a quick site check can head off most potential problems. This simple bit of discipline is what separates a smooth job from a frustrating one. A solid substrate and an organised workflow are the foundations of a quality finish.

Run through this checklist to get your team started on the right foot:

- Substrate Inspection: Check the framing (steel or wood). Is it square, plumb, and free of any issues? A wonky frame will show right through the final surface.

- Material Acclimatisation: Have the boards been stored flat and kept dry on-site? This simple step prevents warping before they even go up.

- Tools and PPE Ready: Do you have everything you need, like specialised blades and the right fasteners, all in good working order? Is all the safety gear out and ready for the crew?

- Layout and Planning: Have you mapped out the board layout? Planning ahead minimises cuts and waste, and ensures your joints line up with the architectural drawings.

A successful fiber cement board installation is 90% preparation and 10% execution. Taking the time to verify the frame, plan your layout, and prepare the right tools will save countless hours and prevent rework down the line.

Precision Cutting and Effective Dust Control

Let's be clear: cutting fiber cement board creates fine silica dust, and you need a plan to manage it safely. The aim is a clean, precise cut while keeping airborne particles to an absolute minimum. Using the right blade isn't optional—it's essential.

For the cleanest cuts, you need a circular saw fitted with a polycrystalline diamond (PCD) tipped blade. These blades are built to handle the tough, abrasive nature of cement. They'll outlast carbide blades by a long shot and give you a much cleaner edge. Pair that with a saw that has a dust collection port hooked up to an industrial vacuum, and you have the best setup for dust control.

Worker safety is non-negotiable when you're using power tools or handling the sharp edges of these boards. Everyone must be wearing the proper personal protective equipment—think durable cut-resistant gloves, safety glasses, and respiratory masks at all times.

Fastening and Jointing for a Flawless Finish

The final stage is all about securing the boards and treating the joints to create a solid, weather-tight surface. The fasteners and jointing methods you use will depend on the frame material and the look you're going for.

Fastening Best Practices:

- For Steel Frames: Always use self-drilling, corrosion-resistant screws made specifically for fiber cement.

- For Wood Frames: Go for hot-dip galvanised or stainless steel nails or screws to stop rust in its tracks.

- Placement is Key: Drive fasteners perpendicular to the board, setting them just slightly below the surface without cracking the face. Stick to the manufacturer's specs for edge and intermediate distances.

Once the boards are up, getting those seamless joints is all about the details. For tapered-edge boards, use a quality jointing compound over embedded fiberglass tape. This lets your finishers sand the surface perfectly smooth for a flawless, monolithic look before painting. If you're using square-edge boards for an expressed joint design, keep the gaps consistent and fill them with a flexible, UV-resistant sealant to block out any moisture.

Meeting UAE Fire Safety and Building Codes

In the UAE's construction world, you don't just follow the building regulations—you live by them. It's not just about good practice; it’s a strict requirement for getting anything built. Every single material, down to the last screw, has to meet tough local standards, especially when it comes to fire safety.

This is exactly where high-performance fiber cement board proves its worth. For any contractor trying to move a project from blueprint to reality, understanding the UAE Fire and Life Safety Code is non-negotiable. Authorities like the Dubai Civil Defence (DCD) are incredibly rigorous. Specifying a material that doesn't cut it can bring your project to a grinding halt with failed inspections, rework orders, and brutal delays. That's a headache no project manager wants.

The Power of a Class A Fire Rating

So, what’s the secret to compliance? It comes down to the basic makeup of fiber cement board. The material is fundamentally non-combustible. Put simply, it won’t catch fire, burn, or add fuel to a blaze. This performance is what earns it a Class A fire rating, the highest possible classification for any building material.

On site, this rating is everything. For critical areas like facades, corridors, and any fire-rated wall or ceiling assembly, fiber cement board is your first line of defence. It helps contain a fire and dramatically slows its spread, buying precious time for people to evacuate and for emergency services to arrive. It's a cornerstone of any solid passive fire protection strategy.

Think of it this way: using a material with a proven Class A rating is the most straightforward path to satisfying the safety-first mandate of UAE building codes. It takes the guesswork out of approvals and gives you documented proof of compliance. That means peace of mind for you and your client.

Streamlining Approvals and Preventing Delays

Choosing the right fiber cement board from day one is a smart, strategic move. When the authorities review your plans and see a Class A, non-combustible material specified for high-risk areas like external cladding or escape routes, the whole approval process gets a lot smoother.

You're essentially getting ahead of the problem. Instead of fielding difficult questions about your material choices, you're showing a clear commitment to safety from the outset. This foresight doesn't just sidestep the dreaded red stamp from inspectors; it builds your reputation as a contractor who gets it right the first time. To keep up with what's next, it's worth reading up on the upcoming 2026 fire safety codes in Dubai.

Aligning with Green Building Initiatives

Compliance in the UAE isn't just about fire safety anymore. Sustainability is now a huge piece of the puzzle. Green building initiatives like Estidama in Abu Dhabi and Dubai's Al Sa'fat rating system are changing the game. These programmes push for materials that are durable, long-lasting, and better for the environment.

Fiber cement board fits perfectly into this modern vision. Its incredible durability means it doesn't need to be replaced often, which cuts down on long-term waste. It's made from natural, often locally sourced raw materials, which helps create a more sustainable supply chain. By specifying fiber cement, you're not just meeting today’s codes—you’re building for the future and aligning your projects with the UAE's goal for a greener, more resilient country.

Procurement and Long-Term Maintenance Strategies

Getting fiber cement boards integrated into your project goes way beyond just the installation. It’s about smart procurement upfront and having a clear plan for long-term care. For any project manager, this means juggling logistics, from ordering standard sizes to factoring in the lead times on any custom cuts. Nailing this part is what keeps your project on schedule and your budget in the black.

This is where a solid local distributor in the UAE becomes your best asset. A good supplier is more than just a vendor; they're a logistics partner. They make sure your materials get to the site when you need them, whether you're ordering wholesale pallets or need bespoke dimensions for a standout architectural feature. In the fast-moving UAE construction scene, that kind of reliable supply chain is a massive advantage.

For accurate project planning and material estimation, tools like Exayard construction takeoff software can be a game-changer, helping you tighten up cost control and better manage your timelines.

Smart Sourcing for UAE Projects

Your sourcing strategy can make or break your bottom line and project schedule. It isn't just about finding the lowest price per panel; it's about the total value a supplier brings to the table. Look for distributors who offer consolidated procurement, letting you bundle your fiber cement boards with other essential materials. This simplifies everything from deliveries to invoicing.

To keep your project running like a well-oiled machine, here are a few procurement tips:

- Verify Stock Levels: Before you commit, always confirm the availability of standard sizes. You don’t want a simple stock issue causing a delay.

- Plan for Custom Orders: Need custom dimensions or finishes? Factor in longer lead times right from the start. We're often talking several weeks.

- Clarify Delivery Logistics: Check if your supplier delivers directly to sites across the Emirates. This can save you a huge headache and the cost of organising secondary transport.

- Request Technical Data: Make sure your supplier hands over all the paperwork you need, like manufacturer warranties and technical data sheets for your compliance checks.

The real goal of procurement isn't just to buy materials. It's to build a supply chain you can count on. A strong relationship with your local distributor means you get the right product, expert advice, and the logistical muscle to keep your project moving forward without a hitch.

Long-Term Maintenance for Lasting Performance

One of the biggest selling points for fiber cement board is how little looking after it needs. But let's be clear: "low maintenance" isn't "no maintenance". A simple, proactive routine of inspection and cleaning will keep the material looking great and performing perfectly for decades, protecting the building's value long after you've handed over the keys. For a closer look at sourcing strategies, check out our procurement manager's guide to sourcing in Dubai.

A simple annual walk-around is usually all it takes. During the inspection, keep an eye out for any damage to the boards or the sealant in the joints. If you spot any sealant that's cracked or pulling away, get it removed and replaced with a high-quality, flexible caulk to stop any moisture from getting in.

As for cleaning, a gentle wash with a soft brush and some mild detergent is all you need to get rid of the dust and grime that builds up over time. This straightforward approach keeps the building looking sharp and minimises lifecycle costs.

Your Questions Answered: Fiber Cement Board in Practice

Even after you've got the specs down, there are always those practical, on-the-ground questions that pop up. Let's tackle some of the most common queries we get from contractors and finishing crews across the UAE, so you can move forward with total confidence.

How Does This Stuff Hold Up in UAE Heat and Humidity?

It’s built for it. A fiber cement board is incredibly stable, which means it won’t swell up, shrink, or start warping when the temperature swings from a scorching afternoon to a cooler, humid evening. That’s a huge deal here.

Think about what kills other materials: rot, mould, and pests. Fiber cement is immune to all of them. It also doesn't go brittle after years under the intense sun, making it the perfect fit for a long-lasting finish in our tough coastal and desert climates.

The bottom line is stability. When other materials crack under the pressure of constant heat and moisture, fiber cement holds its shape and integrity. That means a durable finish without the headache of costly callbacks and repairs.

Can We Paint Fiber Cement Boards to Match Our Colour Scheme?

Of course. That’s one of its biggest advantages. Most boards arrive already primed and ready for whichever topcoat you need, giving you complete design freedom.

For the best result that will last, always go for a high-quality, 100% acrylic exterior paint. This type of paint is formulated to handle the powerful UAE sun without fading or peeling. Just make sure to follow the paint manufacturer’s guide to the letter—it’s the key to a professional finish that stands the test of time.

What's the Best Way to Cut Fiber Cement Board on Site?

You'll want a circular saw, but not with a standard blade. Equip it with a polycrystalline diamond (PCD) tipped blade. These blades are specifically engineered for the abrasive nature of cement, giving you a clean, sharp edge every single time while kicking up less dust.

Speaking of dust, managing it is non-negotiable. The best practice is to hook up your saw's dust port to an industrial vacuum. This keeps your crew safe from breathing in harmful silica dust and ensures you’re staying compliant with site safety rules.

Is Fiber Cement Board More Expensive Than Gypsum or Vinyl?

Upfront, the ticket price might look a bit higher than some alternatives. But you have to look at the total cost of ownership, and that’s where fiber cement really wins.

This is a classic case of investing a little more at the start to save a lot down the road. Its sheer durability and resistance to fire, water, and pests mean you’re not spending money on constant maintenance, repairs, or replacements like you would with other materials. Over the long haul, choosing fiber cement board is the smarter financial move and an investment in the building's resilience and value.

For all your project needs, from high-performance fiber cement boards to a complete range of construction hardware, Yasu Trading Co. LLC is your trusted B2B partner in the UAE. We provide municipality-compliant products with reliable, site-direct delivery to keep your project on schedule. Explore our full range of building materials on yasutrading.com.