PP Corrugated Sheets in Dubai: A Contractor's Guide

If you're a contractor in Dubai looking for a versatile, tough, and waterproof material for site protection, then PP corrugated sheets are what you need. Think of them as a kind of high-tech plastic cardboard. They're incredibly lightweight but offer fantastic resistance to water, chemicals, and general wear and tear, making them a staple on any modern construction project.

What Are PP Corrugated Sheets?

PP corrugated sheets are a lightweight, twin-wall plastic material made from polypropylene, offering a strong yet easy-to-handle alternative to plywood or cardboard. Their strength comes from a clever twin-wall design: two flat outer layers are fused to a central core of vertical plastic ribs, making them surprisingly strong yet so light.

On a fast-paced Dubai construction site, this design is a real game-changer. Plywood is heavy and warps when it gets wet, and we all know what happens to standard cardboard at the first sign of moisture. PP corrugated sheets, on the other hand, just shrug off rain, spills, and humidity, making them the perfect choice for protecting valuable surfaces and materials.

Why are these sheets perfect for Dubai?

These sheets are ideal for Dubai because they are completely waterproof, chemical-resistant, and tough enough for reuse, perfectly suiting the demanding local construction environment. The UAE's climate and high project standards require materials that can keep up, and PP corrugated sheets really shine where traditional options fall short.

- Totally Waterproof: They simply don't absorb water. This means no mould, no rot, and no weak spots that could compromise protection and create a safety issue on site.

- Resistant to Chemicals: These sheets hold up against common construction chemicals, oils, and solvents, so you can count on them to protect surfaces during all phases of a project.

- Tough and Reusable: Built to last, these sheets can be used again and again on different jobs. This gives you a great return on your investment and helps cut down on site waste.

This kind of durability is vital for meeting the high UAE construction standards, which place a huge emphasis on site safety and protecting finished work. As a leading building materials distributor, we at Yasu Trading know these local requirements inside and out. We're constantly supplying top-grade pp corrugated sheets in Dubai to protect everything from newly laid marble floors and glass panels to delicate MEP equipment, preventing expensive damage and the headache of rework.

Using PP corrugated sheets for temporary protection is a smart move. Contractors can safeguard their investment in high-end finishes, making sure the final handover reflects the premium quality expected in Dubai's competitive property market.

Is there a growing demand for these sheets in the region?

Yes, the demand is growing rapidly as contractors recognize their value for protecting and packaging building materials, aligning with the broader growth of the UAE's packaging market. This shift is part of a bigger industry trend. The UAE's corrugated board packaging market was valued at USD 1.1 billion in 2024 and is expected to hit USD 1.85 billion by 2032. You can dig into more data on the UAE's packaging market growth to see the bigger picture.

As a trusted supplier in Dubai, Yasu Trading gives contractors easy access to this indispensable material. We help them keep their projects on schedule and within budget by preventing avoidable damage. In the end, these sheets are a simple, effective insurance policy against the daily chaos of a construction site.

Where are PP corrugated sheets used on UAE job sites?

It’s one thing to talk about the technical specs of pp corrugated sheets in Dubai, but their real worth shines through on a busy construction site. Think of them as the ultimate problem-solvers for the day-to-day grind. Across the UAE, from the skeletal frames of new skyscrapers to the finishing touches on a luxury villa, these sheets are quietly playing a crucial role.

What makes them so popular? It's simple: they're incredibly easy to work with. One person can haul a stack of them, trim a sheet to the perfect size with just a utility knife, and fix it in place in minutes. Compare that to lugging around heavy plywood or metal sheets, and you immediately see the savings in time and manpower—a huge win in Dubai's fast-paced construction world.

What is the most common use for PP corrugated sheets in construction?

The most common use for PP corrugated sheets in construction is temporary surface protection. They serve as a durable shield for high-value finishes like marble floors, tiles, joinery, and glass panels against scratches, paint splatters, and construction debris.

This protective layer is absolutely vital for delivering the flawless finish clients expect. It helps contractors sidestep the nightmare of last-minute, costly repairs right before handover. Spill a can of paint on cardboard, and you have a mess that seeps through. Spill it on a PP corrugated sheet, and you just wipe it clean. The floor underneath remains untouched.

Any good building materials distributor will offer different thicknesses. You might use a lighter grade for walls but will want something much more robust for protecting a main corridor with heavy foot traffic.

How do these sheets protect assets and maintain site safety?

These sheets protect valuable assets by acting as a shield for walls, columns, and windows, while also serving as waterproof barriers to maintain site safety and cleanliness. This versatility helps keep a site safe and up to UAE construction standards.

- Wall and Column Cladding: A few strips of tape are all it takes to wrap pillars, walls, and door frames, shielding them from dents and scrapes as equipment and materials are moved around.

- Window and Glass Protection: They create a solid barrier against plaster, paint overspray, and accidental impacts on expensive glass installations, which saves a fortune in cleaning and potential replacement costs.

- Waterproofing and Dust Barriers: Because they're completely waterproof, you can quickly create temporary walls to contain dust during sanding or protect a finished area from water during plumbing tests or a rare downpour.

For projects needing an even higher level of protection for delicate items, it's worth checking out materials like bubble guard, which provides extra cushioning. You can dive deeper into that in our guide on PP bubble sheets in Dubai.

One of the biggest wins with PP corrugated sheets is their reusability. A contractor might use a set to protect floors on one project, then take those same sheets to the next job and use them as formwork liners or for packaging materials. That kind of lifecycle drastically cuts down on waste and material costs.

How are these sheets used for signage and hoardings?

Their smooth, printable surface and all-weather durability make these sheets an excellent and cost-effective material for temporary site signage and hoardings. Plywood will warp and delaminate in the Dubai heat and humidity, and metal can rust. PP corrugated sheets, on the other hand, hold up brilliantly, keeping safety warnings and directional signs crisp and readable for months on end.

This isn't just a matter of convenience; it's a critical safety issue. As a go-to supplier in Dubai, we often supply sheets in bright colours like yellow or red to make safety notices impossible to miss. It’s an effective and highly economical way for contractors to meet their health and safety duties. Plus, being so light, they are incredibly easy to mount onto temporary fences and hoardings.

How do PP corrugated sheets compare to traditional materials?

To really appreciate why PP corrugated sheets have become so common on Dubai construction sites, it helps to see how they stack up against the materials they often replace. Each material has its place, but for temporary protection and signage, the advantages of PP corrugated sheets are clear.

| Feature | PP Corrugated Sheet | Plywood | Metal Sheet (e.g., Aluminium) | Cardboard |

|---|---|---|---|---|

| Water Resistance | 100% waterproof. Wipes clean, doesn't degrade. | Poor. Swells, warps, and delaminates when wet. | Excellent. Rust-resistant (Aluminium). | Very poor. Disintegrates when wet. |

| Weight & Handling | Extremely lightweight. Easy for one person to carry. | Heavy and cumbersome. Often requires two people. | Lightweight but can have sharp edges. | Very lightweight. |

| Durability & Impact | Good impact resistance. Flexible, doesn't crack easily. | Strong but can splinter. Prone to dents. | Very high impact resistance. Can be dented. | Poor. Easily torn and punctured. |

| Cost-Effectiveness | Highly reusable, low initial cost. | Moderate cost but low reusability once damaged. | High initial cost. Recyclable but not easily reused. | Very low cost, but single-use only. |

| Workability | Cuts easily with a standard utility knife. | Requires a saw for cutting. Creates dust. | Needs specialised tools (shears) to cut. | Tears easily, but not precise. |

| Site Safety | No splinters or sharp edges. Can be brightly coloured. | Risk of splinters. | Potential for sharp, hazardous edges after cutting. | Can become a slippery hazard when wet. |

As the table shows, while materials like plywood and metal have their strengths in structural applications, they are often overkill and impractical for temporary uses. PP corrugated sheets hit the sweet spot of being durable, lightweight, waterproof, and cost-effective, making them the smarter choice for protection, barriers, and signage on a modern UAE construction site.

How do you select the right PP corrugated sheet?

Choosing the right pp corrugated sheets in Dubai isn’t just about picking a size off a shelf. It’s about matching the material’s properties to the specific demands of your job site. Get it right, and you ensure your project stays protected and compliant. Get it wrong, and you’re looking at costly damages and frustrating delays.

Think of it like choosing the right tool for the job. You wouldn't use a tiny hammer to drive a railway spike, right? It’s the same principle here. The thickness, grade, and any special treatments of your corrugated sheets have to line up with what you’re using them for, whether that's protecting the marble floors in a luxury villa or putting up safety signs in the scorching desert sun.

Any decent building materials distributor can give you technical advice, but a little foundational knowledge empowers you to ask for exactly what your project needs. Let's break down the key factors you need to think about.

What sheet thickness is needed for floor protection?

For light-duty areas, a 3mm sheet is often sufficient, but for heavy-duty protection in high-traffic corridors, you should use a robust 5mm sheet or thicker. The required thickness is a direct result of foot traffic and the risk of impact.

This isn't just a suggestion—it's critical for meeting UAE construction standards, which are big on preserving finished surfaces. A thicker sheet offers far better cushioning and impact resistance. It’s the difference between a dropped hammer causing a chip and that expensive new flooring remaining pristine.

Why is UV resistance critical for outdoor signage in Dubai?

UV resistance is critical because standard polypropylene will become brittle, crack, and fade quickly under Dubai's intense sunlight. UV-stabilised sheets contain special additives that protect the material's integrity and colour, ensuring signs remain readable and professional for the project's duration.

This is a non-negotiable feature for any outdoor use. A faded safety sign isn't just ugly; it’s a potential liability. As a supplier in Dubai with years of experience, we always push for UV-treated sheets for hoardings, directional signs, and any protective layers left exposed to the sun.

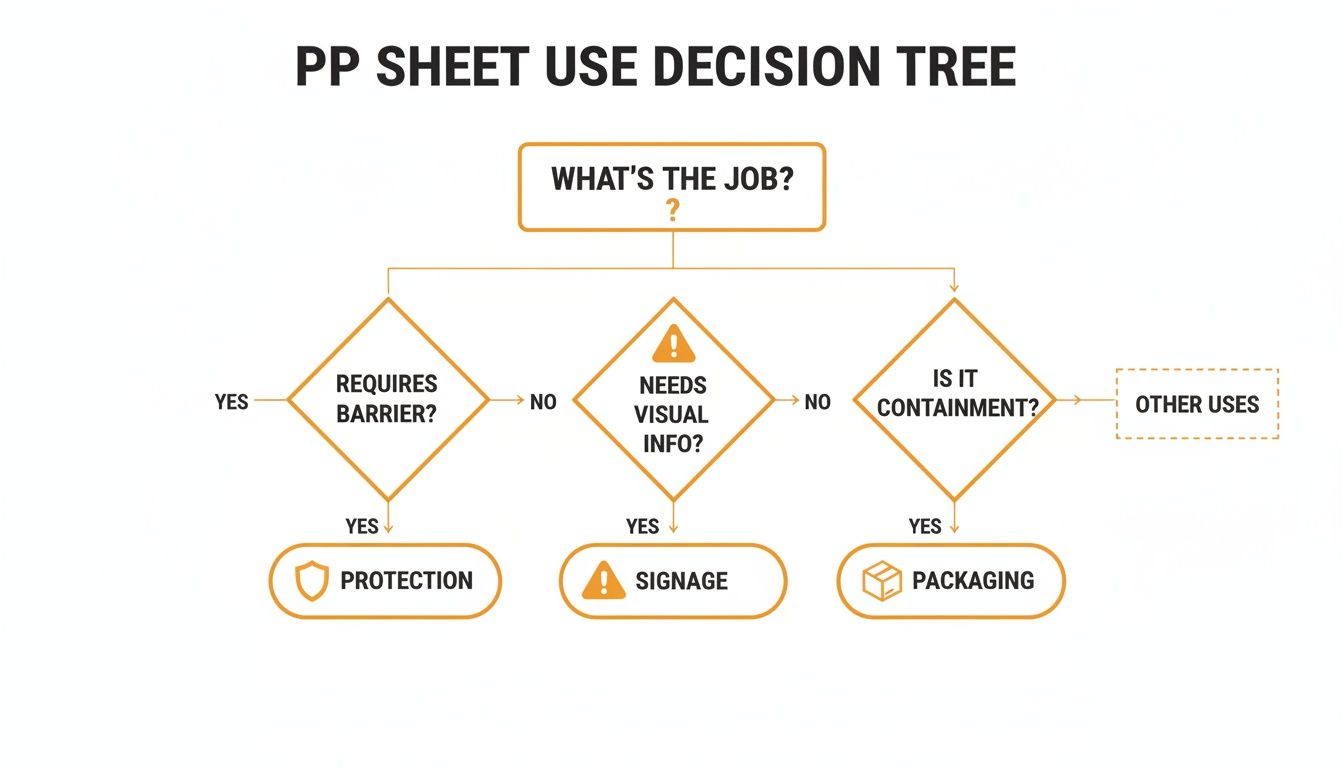

This decision tree helps visualise how to match sheet properties to different on-site tasks.

As you can see, what you're using it for—protection, signage, or packaging—is the first and most important question to answer. Everything else follows from there.

Are special additives like flame retardancy necessary?

Yes, flame-retardant additives are essential in environments where fire safety is a top priority, such as high-rise buildings, hospitals, and data centres. Local regulations often mandate these specially treated sheets, which self-extinguish and prevent the spread of flames.

The demand for these specialised sheets is on the rise as the UAE's construction industry sharpens its focus on safety and risk management. It's part of a bigger picture; the corrugated packaging market is seeing a 6.2% CAGR from 2024-2030. The smart engineering of different flute types, from E-flute to B-flute, delivers up to 50% better impact resistance—vital for protecting materials as Dubai expects a 21% increase in packaged goods demand by 2026.

When in doubt, always talk to your project's safety officer and your materials supplier. Having the right certification for flame-retardant sheets can be a critical piece of your project's compliance paperwork.

Beyond the main construction site, these sheets are also great for more specific uses, like lightweight and temporary shipping container cladding solutions for site offices or storage units. Their weather resistance and simple installation make them a practical choice for temporary structures.

By carefully weighing these factors—thickness, UV resistance, and special additives—you can confidently choose the perfect pp corrugated sheets in Dubai for any job, ensuring you get the best value and protection for your project.

How do you handle and install corrugated sheets?

Getting the best performance and lifespan from your pp corrugated sheets in Dubai really boils down to how you handle and install them. These sheets are tough, no doubt. But with a few smart on-site practices, you can easily turn what might seem like a disposable item into a reusable asset, saving you a good chunk of change across multiple projects.

Proper care starts the moment they arrive from your building materials distributor. Even though they're durable, it’s always best to store them flat and out of direct, intense sunlight—unless they're specifically UV-treated—to avoid any warping. A quick check to ensure they're kept clean and dry means they're ready to go the second you need them.

This kind of practical, on-the-ground knowledge is what separates a good job from a great one. It’s not just about using materials; it’s about using them intelligently to cut down on waste and protect your budget.

How can you cut PP corrugated sheets without special tools?

You can easily cut PP corrugated sheets with a standard, sharp utility knife. For the cleanest cut, lay the sheet on a flat surface and slice along the direction of the flutes; to cut across the flutes, use a straightedge to guide your knife.

This simplicity is one of the best things about these sheets. You don’t need any fancy equipment. If you need to cut across the flutes, apply firm, steady pressure. You might need to make two or three passes to get all the way through, but this little bit of extra effort pays off with a clean, professional edge instead of a jagged mess. This means anyone on your crew can customise sheets to fit any space on the fly.

How do you secure sheets to different surfaces?

The best method depends on the surface, but always start with a clean, dry area. For floors, overlap the sheets and use high-quality tape on the seams; for walls and glass, use double-sided or low-tack painter's tape to avoid damaging the finish.

Here are a few go-to methods that work well on typical Dubai job sites:

- Floors (Marble, Tile, Concrete): Overlap the sheets by a few centimetres and tape down the seams. A quality, residue-free duct tape or gaffer tape is perfect for creating a sealed barrier that stops dust, debris, and spills from getting through.

- Walls and Vertical Surfaces: For temporary, lightweight protection, good double-sided tape often does the trick. In high-traffic zones or for a more secure hold, use a low-tack painter's tape around the edges. It’ll hold firm without pulling off paint or damaging the finish when it's time for removal.

- Glass and Windows: Stick with a low-adhesion painter’s tape. It provides enough grip to keep the sheet in place but peels off cleanly without leaving that frustrating sticky residue—a small detail that makes a big difference during final project handover.

Just a heads-up: the heat in the UAE can be tough on adhesives. Always choose high-quality tapes that are rated for higher temperatures. This will stop them from peeling off in the heat or, even worse, leaving a sticky mess behind. A good supplier in Dubai can usually point you to tapes that are proven to work in our climate.

How can you maintain and store sheets for reuse?

To make your corrugated sheets last for project after project, clean them with a simple wipe-down, inspect them for major damage, and store them flat in a covered area. This quick process takes only a few minutes after each job.

- Clean Them Up: Give the sheets a good sweep or wipe-down to get rid of dust and dirt. If you’ve got stubborn grime or dried spills, a bit of water and a mild detergent will clean them up nicely.

- Give Them a Quick Inspection: Look over each sheet for any major cuts, punctures, or breaks. A little wear and tear is expected, but badly damaged sheets should be set aside for recycling.

- Store Them Right: Once they're clean and dry, stack them flat in a covered area. Storing them on their edge can cause them to bend and warp over time, so a flat stack is always your best bet.

Following these straightforward steps can dramatically extend the life of your sheets. It’s not just more cost-effective; it also aligns with the growing focus on sustainability in UAE construction standards. You'll be helping your company reduce its environmental impact, one project at a time.

How do you cost and source sheets from a Dubai supplier?

Getting your project budget right from the start is non-negotiable. When it comes to PP corrugated sheets in Dubai, understanding what drives the price is key to accurate planning and avoiding those last-minute, unwelcome surprises. The cost isn't a simple one-size-fits-all figure; it’s directly tied to the specific job you need the sheets to do.

Think of it like buying a work vehicle. A standard pickup might be fine for small jobs, but if you're hauling tonnes of material across a demanding site, you'll need something far more robust. It's the same principle with these sheets. The final price tag is a reflection of several key factors tailored to your project's real-world needs.

What factors influence the price of PP corrugated sheets?

The price is primarily influenced by four factors: thickness (GSM), sheet size, special additives like UV or flame retardants, and the total order volume. Any good supplier in Dubai will be completely transparent about how these variables shape your final quote.

- Thickness (GSM): This is the single biggest factor. A standard 3mm sheet for simple wall protection is naturally going to be more budget-friendly than a heavy-duty 5mm sheet engineered to take a beating from machinery in a high-traffic corridor.

- Sheet Size: The standard 2.44m x 1.22m sheet is the most economical. If you need custom dimensions cut for a specific application, that will influence the price per unit.

- Special Additives: Do you need sheets that can stand up to the relentless UAE sun or meet strict fire safety codes? Adding UV-stabilised or flame-retardant properties involves extra manufacturing steps, which adds to the cost but is often a critical requirement for compliance and long-term performance.

- Order Volume: This one’s simple. As with most building materials, placing a larger bulk order almost always brings down the per-sheet cost, making it a much more economical choice for large-scale developments.

Nailing these details down before you ask for a price means you’ll get a precise quote for exactly what you need. You won't end up paying for features you don't require or, even worse, under-specifying and having the material fail on you.

Why source from a local building materials distributor?

Sourcing locally ensures rapid delivery to your site, preventing costly project delays and keeping your timeline intact. A local partner like Yasu Trading Co. LLC isn't just selling you a product; we're offering a complete procurement solution designed for the breakneck pace of the UAE's construction industry.

Instead of languishing for weeks waiting on an international shipment, you get your materials delivered directly to your site, fast. For a deeper dive into this, check out our article on the benefits of partnering with top-tier building materials suppliers in the region.

This need for a strong local supply chain is clear when you look at the market. Dubai is a hub for the GCC's corrugated packaging market, which is growing at a 5.28% CAGR and is on track to hit USD 4.09 billion by 2026. This boom shows a huge demand for materials like PP corrugated sheets. We're seeing the fastest growth in variants like double-wall PP sheets for superior protection, while recycled grades are becoming essential to meet UAE construction standards and green building initiatives. You can learn more about these market dynamics and what they mean for the industry.

How does the quoting and delivery process work?

The process is simple: you specify your needs, receive a clear quote with wholesale pricing, and upon confirmation, we schedule a rapid, direct-to-site delivery. At Yasu Trading, we’ve honed our system to be as efficient and straightforward as possible for contractors who have a million other things to worry about.

Our focus is on delivering total value, not just a low price. That means you get competitive wholesale pricing backed by the logistical support and technical know-how to make sure your project runs without a hitch.

Here’s how it works:

- Tell Us What You Need: Just get in touch with our team and specify the sheet thickness, size, quantity, and any special features like UV or flame-retardant additives.

- Get a Clear Quote: We’ll send back a detailed, itemised quotation with competitive wholesale pricing. No hidden costs, no surprises.

- Confirm and Get It Delivered: Once you give the go-ahead, we schedule a rapid, site-direct delivery to your project, whether it’s in Dubai, Sharjah, Abu Dhabi, or the Northern Emirates.

This no-fuss approach guarantees you get the right materials on-site and on time, every single time. Your crew stays productive, and your project stays on schedule.

Why choose Yasu Trading as your supply partner?

Picking the right material is only half the battle. To keep your project on track, you need a supplier who’s more than just a name on an invoice. For contractors juggling tight deadlines and complex logistics, a dependable supply chain isn’t just a nice-to-have—it's essential. That’s where Yasu Trading Co. LLC steps in, not as a vendor, but as your partner in procurement.

With over 20 years of hands-on experience, we know the ins and outs of the UAE's demanding construction market. We don’t just sell PP corrugated sheets in Dubai; we deliver practical solutions that help MEP, civil, and finishing contractors sidestep logistical headaches and keep their projects moving forward.

What is our track record as a reliable supplier in Dubai?

Our reliability is built on a deep, ready-to-ship inventory, a strategic location in Deira, and a commitment to stocking high-quality, municipality-compliant products. This ensures fast deliveries and that everything arriving at your site meets all local regulations, preventing delays and downtime for your crew.

Think of us as an extension of your procurement team—we’re here to consolidate your orders, source what you need, and get it to you, right when you need it.

At Yasu Trading, we see our role as a supportive partnership, not just a transaction. Our job is to solve your material sourcing challenges so you can focus on what you do best: delivering outstanding work for your clients.

How do we support contractors beyond the basics?

We offer genuine technical advice, sourcing expertise, and order consolidation services to simplify your procurement process. Our team will help you pinpoint the exact specifications for your job, ensuring you comply with all UAE construction standards without overpaying for features you don’t need.

As a trusted building materials distributor, we also pride ourselves on finding those hard-to-get items. This simplifies your procurement, saving you precious time and paperwork. Let us handle the supply chain complexities so you don't have to.

Ready to work with a supplier who truly understands the demands of your project? Contact our expert team today for a competitive quote or technical advice on your next order of PP corrugated sheets.

Frequently Asked Questions About PP Corrugated Sheets

To wrap things up, let's tackle some of the most common questions we hear from site managers and contractors here in the UAE. Think of this as a quick, no-nonsense Q&A to get you the info you need.

Are these sheets really suitable for outdoor use in Dubai's climate?

Yes, but only if they are UV-stabilised to prevent them from becoming brittle and breaking down under the intense Dubai sun. Standard sheets are not suitable for prolonged outdoor exposure.

The UV-treated versions have additives baked in that protect them from this degradation. This makes them the go-to choice for temporary hoardings, site signage, or any external protection that needs to hold up. Any good supplier in Dubai will ask about your intended use and make sure you get the right grade for the job.

Can you recycle PP corrugated sheets in the UAE?

Yes, PP corrugated sheets are 100% recyclable in the UAE and fall under Recycling Code #5. This aligns perfectly with the sustainability and green building goals integral to UAE construction standards.

Smart contractors get even more value by reusing the sheets for different tasks on-site before sending them for recycling. It’s a win for the budget and the environment.

A common myth is that because they're plastic, these sheets are worse for the environment than paper-based alternatives. But when you factor in their high reusability and full recyclability, they often have a much lower environmental footprint than single-use products.

What is the standard sheet size in Dubai?

The industry standard sheet size available from any building materials distributor in Dubai is 2440mm x 1220mm (or 8ft x 4ft). This size is ideal for quickly covering large surface areas with minimal joints.

While that's the standard off-the-shelf size, established suppliers like Yasu Trading can cut sheets to custom dimensions. If your project has unique specs, we can get you the perfect fit.

How do they compare to plywood for floor protection?

PP corrugated sheets are lighter, completely waterproof, and more versatile than plywood for temporary floor protection. While plywood might offer better resistance to a very heavy, sharp impact, corrugated sheets provide excellent protection against scratches, spills, and foot traffic more cost-effectively.

Their lightweight nature saves time and labour, and unlike plywood, they won't warp, swell, or disintegrate when exposed to water or chemical spills.

When you need a partner who gets the demands of your project, you can count on Yasu Trading Co. LLC. We supply high-quality materials and the logistical support to keep your site running without a hitch. Take a look at our full range of construction solutions and see how we can help you build better at https://yasutrading.com.