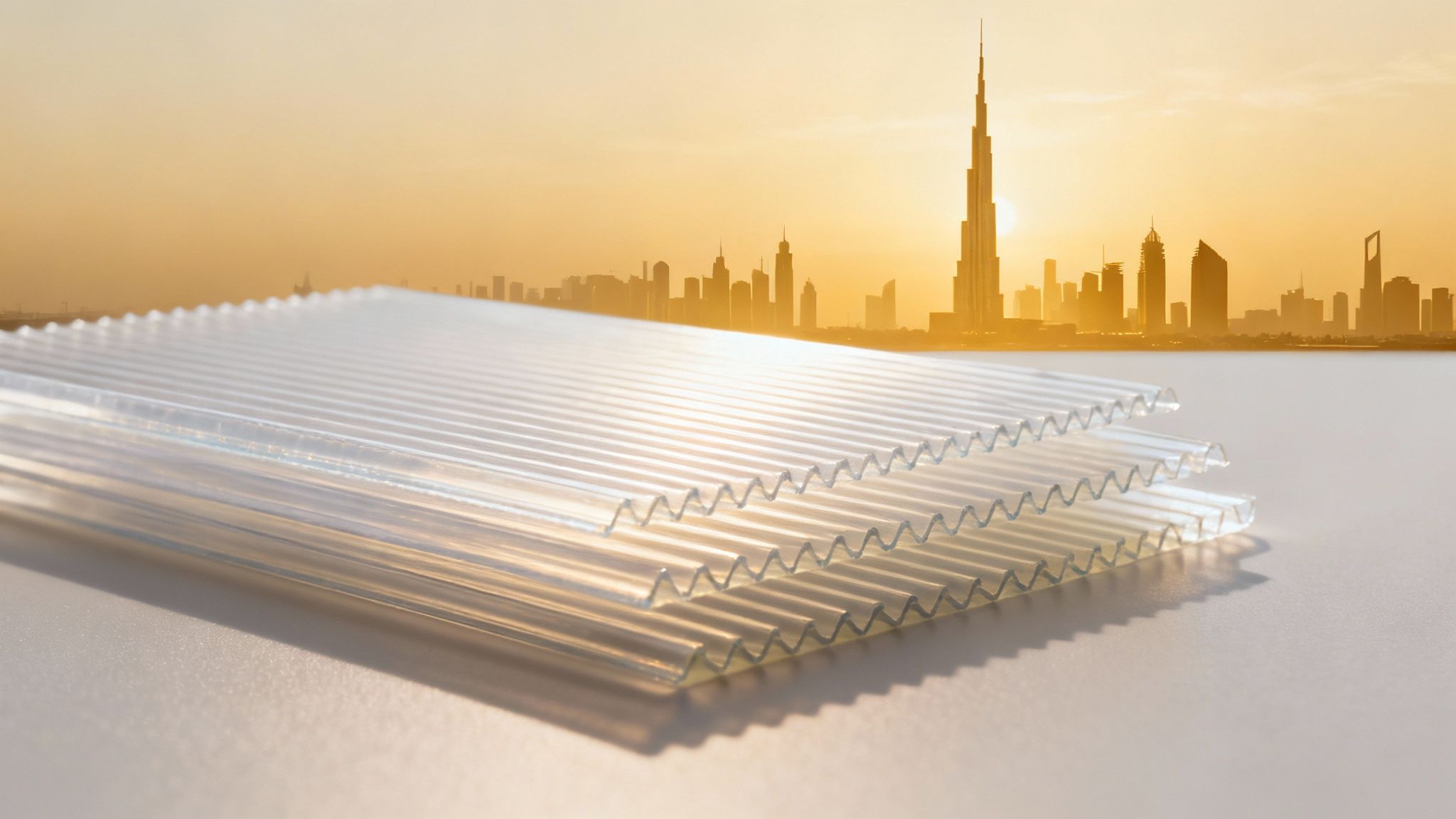

Your Guide to Sourcing the Best PP Corrugated Sheets in Dubai

When sourcing PP corrugated sheets in Dubai, making the right choice of supplier is crucial for ensuring quality, timely delivery, and competitive pricing. The market offers a range of options, but discerning businesses look for partners who understand their specific needs. Key factors to consider include the supplier's reputation for material quality and consistency, their ability to offer custom fabrication and printing services, and their commitment to sustainable practices. A reliable supplier in Dubai will not only provide the sheets but also offer expertise and support to help you optimize their use for your particular application.

These aren't just plastic panels; they're a strategic tool for boosting site efficiency, protecting valuable assets, and keeping your project on track, bringing together a killer combination of low weight, high strength, and impressive reusability that's a must-have for upholding demanding UAE construction standards.

Why are PP corrugated sheets a secret weapon on Dubai sites?

In Dubai’s demanding construction scene, where time is money, every material choice counts. PP corrugated sheets, often called Correx boards, have become the go-to because they solve multiple problems at once, outperforming traditional materials like plywood or cardboard by offering superior protection without the added weight or cost.

Think about it. You've just installed a beautiful marble floor in a high-end hotel lobby. You can't just throw down some plywood—it's heavy, abrasive, and could easily scratch the finish. Cardboard? It's useless the second it gets wet. But a PP corrugated sheet provides a cushioned, waterproof barrier that can take the abuse of foot traffic, dropped tools, and spills, ensuring that pristine finish stays that way until handover.

For any building materials distributor in the region, stocking high-quality PP sheets isn't just an option; it's a necessity to support local contractors.

Here’s a quick rundown of why these sheets are so valuable on any UAE project site:

Benefit: Lightweight

Impact on Construction Projects: Easy for a single worker to carry, cut, and install, saving on labour and time.

Relevance to Dubai and UAE Climate: Resists humidity and moisture, unlike cardboard which degrades quickly.

Benefit: Durable & Impact-Resistant

Impact on Construction Projects: Protects expensive finishes (floors, doors, windows) from scratches, dents, and spills during construction.

Relevance to Dubai and UAE Climate: UV-stabilised grades won't become brittle or break down under intense sun exposure.

Benefit: Waterproof & Chemical-Resistant

Impact on Construction Projects: Impervious to water, oils, and common construction chemicals, making cleanup easy and preventing damage.

Relevance to Dubai and UAE Climate: Ideal for protection during wet works (tiling, plastering) and won't rot or grow mould in humid conditions.

Benefit: Reusable & Recyclable

Impact on Construction Projects: Can be used multiple times across different project phases or sites, reducing material waste and overall cost.

Relevance to Dubai and UAE Climate: Supports sustainability goals and green building initiatives increasingly important in the UAE.

Benefit: Versatile

Impact on Construction Projects: Used for floor protection, temporary signage, formwork, hoarding, and waterproofing membranes.

Relevance to Dubai and UAE Climate: Its adaptability makes it a single-stock solution for multiple site challenges, simplifying procurement.

In short, PP corrugated sheets deliver a practical and financial edge that’s hard to ignore in this competitive market.

What value do PP sheets add beyond simple protection?

The real value here goes way beyond just covering a floor. These sheets are a versatile workhorse for keeping a project running smoothly and meeting the sky-high expectations of the local market, making a real difference on the ground.

- Boosting Site Safety: You can use them to cover up unfinished openings, shield workers from sharp edges, or create temporary, high-visibility safety barriers. It’s a simple way to help cut down on workplace accidents.

- Making Logistics Easier: Being so lightweight means they're a breeze to transport around a site, cut to size, and put in place. This saves a ton of time and labour compared to lugging around heavier alternatives.

- Protecting Your Investment: They’re perfect for shielding expensive components like windows, doors, and sanitaryware from dust, paint overspray, and impact damage during the final, chaotic stages of a project.

When contractors start using PP corrugated sheets, they're not just buying a product. They're adopting a system that cuts waste, protects investments, and keeps the whole project moving forward without costly setbacks.

How do these sheets help contractors keep pace with the market?

The utility of these sheets is especially critical in the UAE's fast-moving construction landscape. In a market famous for its explosive growth, efficiency is everything. With over 15,000 new projects registered since 2022, contractors are leaning heavily on these durable sheets to protect materials and hit aggressive deadlines.

Their role in everything from protective packaging to temporary site coverings has become fundamental to navigating this high-stakes environment. You can find more insights about the corrugated packaging market on Researchandmarkets.com. A reliable supplier in Dubai gets this and ensures a steady pipeline of quality pp courragate sheets, helping projects stay compliant with UAE construction standards.

What types and grades of PP sheets are available?

Choosing the right pp courragate sheets in dubai is like picking the right tool for the job—the details matter. Not all sheets are created equal, and getting the specs right is what separates a successful project from one plagued by issues, as the cheapest option can lead to poor performance and surprise costs.

When you're looking at a spec sheet, two terms you'll see pop up constantly are GSM (Grams per Square Metre) and thickness. GSM is basically the sheet's density. A higher GSM means more material is packed into the same space, giving you a stronger, tougher sheet. Thickness, on the other hand, is just the height of the sheet's profile, measured in millimetres (mm).

Here's the catch: a thick sheet isn't always a high-GSM sheet. You could have a thin but surprisingly rigid sheet with a high GSM, or a thick, low-GSM sheet that feels flimsy. It's all about finding the right balance for your specific application.

What gives corrugated sheets their strength?

The incredible strength-to-weight ratio of these sheets comes from their internal structure. That wavy, arched layer you see sandwiched between two flat liners is called the "flute," and it's a small marvel of engineering designed to distribute weight and resist impact without adding unnecessary bulk.

Think about the arches of a bridge. They're designed to distribute weight and pressure across the entire structure, letting it handle massive loads without being a solid, heavy block. The flutes in a corrugated sheet do the exact same thing, giving it rigidity and impact resistance without adding unnecessary weight.

This clever design is why a single person can easily carry a sheet that can take the daily abuse of a busy construction site. A good supplier in Dubai will help you pick the right flute profile for what you need, whether it's simple floor protection or something heavy-duty for formwork.

Which specialized grades are best for the Dubai environment?

Standard PP sheets are great all-rounders, but the unique challenges in the UAE often call for something more specialized. Getting these from a knowledgeable building materials distributor is key to ensuring you meet local standards and get the performance you need.

This diagram shows how thinking strategically about your PP sheets can boost safety, efficiency, and sustainability on-site.

Choosing the right grade isn't just about the material; it's a strategic move that affects the very foundations of a successful project.

Here are the most common grades you'll need to consider:

- UV-Stabilised Sheets: Dubai's sun is no joke. It can break down standard plastics, making them brittle and useless. UV-stabilised sheets have additives that fend off solar radiation, making them an absolute must for outdoor uses like site hoarding or temporary signage.

- Fire-Retardant (FR) Grades: On any construction site, safety comes first. FR sheets are treated with chemicals that slow down the spread of flames. This is a critical feature for indoor protection and temporary partitions, and it helps you stay aligned with strict UAE construction standards.

- Anti-Static Sheets: If you're working in a space with sensitive electronics, a stray spark of static electricity can cause serious damage. Anti-static sheets have a special coating that safely gets rid of electrical charges, making them perfect for protecting server rooms or data centres during construction.

Once you understand these different types and grades, you can make a much smarter decision. You’re not just buying a plastic sheet; you're choosing a purpose-built solution designed to perform under pressure, keeping your assets safe and your project on track.

How can you meet UAE construction and sustainability standards?

In Dubai's construction world, regulations are the backbone of every successful project. Choosing the right pp courragate sheets in dubai is a small decision that makes a big difference in compliance, preventing costly stop-work orders or fines for not meeting Dubai's Green Building Regulations.

This is exactly why partnering with a good building materials distributor is so critical. You need someone who lives and breathes these regulations, who can hand you a product and say with confidence, "This meets municipality standards." It's your first line of defence, saving you from the kind of headaches that throw timelines and budgets completely off track.

And it’s not just about ticking a box for structural safety. The bigger picture here is sustainability, a huge part of the UAE's vision for the future.

How do PP corrugated sheets support sustainability goals?

The straightforward answer is that they are 100% recyclable and built to be used again and again. This reusability drastically reduces waste on a job site, directly supporting the sustainability targets set by local authorities.

Choosing these sheets is a practical, no-fuss way to show you’re serious about building responsibly. Instead of tossing single-use plywood or soggy cardboard into a skip, you can just clean off these PP sheets and use them for the next phase, or even on your next project. It's a circular mindset, and it's exactly what modern, sustainable construction is all about.

How do the sheets align with Dubai's Green Building Regulations?

The Dubai Green Building Regulations are all about being smart with resources and slashing waste. PP corrugated sheets are a perfect fit for this philosophy, and they boost your project’s green credentials in a few very real ways.

- Waste Reduction: Because they last so long and can be reused, you drastically reduce the amount of rubbish your site produces. That’s a key metric the authorities look at.

- Recyclability: Once they’ve finally served their purpose after a long life, the sheets can be fully recycled. They don’t end up in a landfill; they become raw material for something new.

- Material Efficiency: They’re incredibly lightweight. That means less fuel and energy to get them to your site compared to heavier materials, which chips away at your project's carbon footprint.

By integrating reusable PP corrugated sheets into your workflow, you’re not just protecting a floor; you’re actively participating in the UAE's push for a more sustainable built environment and reinforcing your project's compliance with green mandates.

Sustainability isn't just a buzzword; it's a massive driver for the adoption of pp courragate sheets in dubai. In the UAE market, recycled plastic and paper variants already command over 56% market share. That number is growing at a 5.6% CAGR as Dubai works towards its goal of net-zero buildings by 2050. The data speaks for itself: in 2023, UAE contractors cut their disposal costs by an average of 20% just by making the switch to recyclable PP sheets—the kind tough enough to handle a scorching 50°C Dubai summer without breaking down. You can discover more insights about the UAE packaging market trends on Grandviewresearch.com.

On top of sustainability, fire safety is non-negotiable. Opting for fire-retardant grade PP sheets, for example, adds another layer of protection to your site, which is a core part of the UAE construction standards. If you want to get into the details, our article on choosing the right fire-rated building materials is a great resource. Ultimately, working with a trusted supplier in Dubai ensures the materials you get tick both the green and the safety boxes, every time.

How to choose the right supplier in Dubai?

When you're sourcing pp courragate sheets in dubai, picking the right supplier is just as crucial as the product itself. A good decision means getting high-quality materials on time and at a fair price—three things that can absolutely make or break your project's budget and schedule.

Sure, the market is crowded with options, but seasoned contractors know what to look for. They aren't just hunting for a vendor; they're looking for a genuine project partner.

What makes a supplier a true project partner?

A true project partner brings value with industry knowledge, logistical strength, and a commitment to your success. They do more than just sell products; they anticipate needs, help you navigate UAE construction standards, and offer cost-effective solutions as an extension of your own procurement team.

Think about it: they should anticipate your needs, help you navigate the specifics of UAE construction standards, and offer solutions that are both practical and cost-effective. Their goal isn't a quick sale; it's building a long-term relationship founded on trust and rock-solid performance.

When you find the right supplier, you're not just buying sheets. You're gaining access to a deep well of local expertise, a reliable inventory, and a logistics network built to keep your project moving forward without a single hitch.

How can you verify a supplier's reputation?

To verify a supplier's reputation, first check their track record and how long they've been in the UAE market. A supplier with years of experience understands local project demands. Additionally, check online reviews, look for case studies, and ask for direct client references to gauge their service quality and reliability.

What are the key criteria for evaluating a supplier?

To cut through the noise, you need a clear way to compare your options. It all boils down to three pillars: product quality, service reliability, and overall value. These are the things that will directly impact your project’s efficiency and the final result.

Here’s a quick checklist to help you evaluate potential suppliers.

Supplier Evaluation Checklist for Dubai Contractors

Finding the right partner requires a bit of due diligence. This table provides a structured approach to help you assess potential suppliers and ensure they meet the specific demands of your construction projects in Dubai.

| Evaluation Criteria | What to Look For | Why It Matters for Your Project |

|---|---|---|

| Inventory Depth & Quality | A wide range of thicknesses, GSMs, and grades (UV-stabilised, FR). Consistent stock levels. | Avoids project delays and compromises. You get the exact sheet for the job every time. |

| Logistics & Delivery | Confirmed site-direct delivery capabilities. Same-day or next-day options in Dubai, Abu Dhabi, etc. | In Dubai's fast-paced environment, a delayed delivery means costly downtime for your crew. |

| Technical Expertise | A team that understands material specs, applications, and local standards. | Invaluable support for choosing the right product, ensuring compliance, and solving on-site challenges. |

| Customisation Services | In-house cutting, printing, and fabrication options. | A one-stop shop saves you time and coordination headaches, especially for signage or specific protection needs. |

| Market Reputation | Proven track record in the UAE. Positive client testimonials and references. | A long-standing, positive reputation is a strong indicator of reliability and consistent performance. |

By using this checklist, you can move past a simple price-to-price comparison. You’re looking for a partner who delivers lasting value.

Let's break down those criteria a bit more:

1. Depth and Quality of Inventory

A supplier’s stock is their backbone. You need a distributor who keeps a massive range of pp courragate sheets in dubai, covering different thicknesses, GSMs, and specialty grades like UV-stabilised or fire-retardant options. This means you can get exactly what you need, when you need it, without having to compromise.

2. Logistics and Delivery Capabilities

On a busy Dubai construction site, speed is everything. A supplier’s delivery promise has to be ironclad. Can they guarantee same-day or next-day delivery straight to your site, whether you're in Jebel Ali, Sharjah, or Downtown? A supplier with a slick logistics network is your best defence against costly project delays.

3. Technical Expertise and Support

Does their team actually know their stuff? A knowledgeable sales team isn't just there to take an order. They should be able to help you choose the right grade for a tricky application, ensuring you hit performance targets and stay compliant. That kind of expert support is gold when you run into an unexpected challenge. For a closer look at the sourcing process, our procurement manager's guide to sourcing building materials in Dubai offers more insight.

4. Customisation and Value-Added Services

Maybe you need sheets cut to a very specific size, or perhaps you want them printed with your company logo for site branding. A top-tier supplier in Dubai should be able to handle this in-house. These fabrication and printing services turn them into a one-stop solution, saving you valuable time and the hassle of coordinating with yet another vendor.

What are the common applications across Dubai's industries?

The real magic of pp courragate sheets in dubai isn't just in the material itself, but in how it solves real-world problems. You’ll find them everywhere, from high-rise construction sites to flashy event setups, making them a workhorse material that contractors, event managers, and logistics pros rely on daily.

Think about it. One day, these sheets are protecting a new hotel's marble floors from scuffs and spills. The next, they're being printed into durable signage for a property launch or forming custom crates for a shipment leaving Jebel Ali. A smart supplier in Dubai knows this, which is why we keep a deep stock—you never know what challenge they’ll be needed for next.

What are the main uses in construction?

On any construction site, PP corrugated sheets primarily serve as surface protection, temporary enclosures, and formwork. Their ability to absorb impact and repel water is crucial for protecting expensive finishes during the final, messy stages of a project—a must for meeting stringent UAE construction standards.

Their light weight is another huge win. A small crew can cover a massive area in no time, which translates directly to labour savings. Imagine trying to cover the entire floor of a new office tower with heavy plywood. It's slow, back-breaking work. With PP corrugated sheets, the same job gets done in a fraction of the time, and you don't have to worry about the protection material scratching the very surface it's supposed to be protecting.

You’ll spot them all over Dubai sites, typically used for:

- High-End Floor Protection: They create a cushioned, waterproof shield over marble, tile, and hardwood, fending off dropped tools, paint, and relentless foot traffic.

- Window and Door Shielding: When the plastering and painting starts, these sheets are a lifesaver. Cut them to size, tape them over glass and frames, and you’ve got perfect protection from scratches and overspray.

- Temporary Partitions and Hoarding: Need to wall off an area quickly? Their rigidity and low weight make them ideal for temporary walls or site hoardings that go up fast and come down just as easily.

How are they used in signage and advertising?

PP corrugated sheets are the go-to material for durable, weather-resistant signs in advertising and real estate. They are lightweight, cost-effective, and provide a smooth surface perfect for high-quality, vibrant printing that stands up to the Dubai sun, especially when using UV-stabilised grades.

The surface is perfectly smooth, making it a great canvas for high-quality, vibrant printing. When you use UV-stabilised grades, those graphics will stand up to the fierce Dubai sun without fading. It's why you see them used for everything from "For Sale" signs on new villa projects to promotional backdrops at major trade shows.

For a real estate developer or an event manager, having access to professional, weather-resistant signage that can be used again and again is a game-changer for the budget. It delivers a sharp, consistent brand image without the constant cost of replacing signs that couldn't handle the elements.

What is their role in logistics and packaging?

In logistics, PP corrugated sheets are used to create lightweight yet incredibly strong custom packaging. They are ideal for building reusable boxes, bins, and dividers (dunnage) that protect sensitive parts during transit while reducing shipping weight and costs.

They're perfect for building reusable boxes, bins, and dividers (what the industry calls "dunnage") to keep sensitive parts safe in transit. The material is also waterproof and resistant to most chemicals, so the containers can be washed down and sent back out for another run. This makes them a far more sustainable—and hygienic—choice than one-and-done cardboard, offering a serious return on investment for any business shipping a high volume of products.

What are the best practices for using and maintaining your sheets?

Buying the right pp courragate sheets in Dubai is the first step, but how you handle and care for them on-site makes the real difference. Following best practices for use and maintenance can stretch their lifespan, cut waste, and ultimately save your project money.

It’s just common sense, really. You wouldn't use a tiny hand saw to cut through a steel beam. In the same way, using the right techniques for cutting, joining, and storing your sheets ensures they do their job properly, again and again. These practices are simple, but they’re incredibly effective.

What is the best way to cut PP corrugated sheets?

The best way to cut PP corrugated sheets is with a sharp utility knife and a straight edge, such as a metal ruler. This method ensures a clean, precise cut without creating frayed edges or plastic dust.

Here’s the process for a perfect cut:

- Measure Twice, Cut Once: Get your tape measure and a marker to draw a clear line.

- Use a Guide: Clamp or hold a metal ruler firmly along your line. It’s your secret weapon against a wobbly, unprofessional cut.

- Score the Surface: On your first pass, just use light pressure to score the top layer. This creates a neat little channel for the blade to follow.

- Finish the Cut: Now, apply steady pressure and make one or two more clean passes to slice right through. Don't try to force it in one go—that’s how you get messy, jagged edges.

How should you secure and join sheets on site?

To secure and join sheets, overlap the edges by at least 5-10 cm and seal the seam with a heavy-duty tape like duct tape. For sensitive surfaces like high-end flooring, use a low-tack painter's tape around the perimeter to prevent residue or damage.

Your choice of tape matters depending on the surface:

- Floors: Stick with a low-tack painter's tape around the edges. It’ll hold everything in place securely but won’t leave behind a sticky mess on that expensive flooring.

- Walls & Glass: Again, a less aggressive tape is your best bet. Just make sure the surface is clean and totally dry before you apply it to get a good stick.

One of the biggest mistakes we see on-site is using tapes that are far too strong for the surface. The last thing you want is to peel off your protective layer and find you've damaged the finish underneath. Always test your tape on a small, hidden spot first, especially on the premium materials common in Dubai projects.

How do you store sheets to maximize their lifespan?

To maximize their lifespan, clean the sheets with a damp cloth and mild soap, let them air dry completely, and then stack them flat on a level surface. Storing them flat and away from direct sunlight or extreme heat prevents them from warping, ensuring they remain reusable for future projects.

This kind of basic maintenance is how you get real value from your investment, aligning perfectly with the UAE construction standards that push for waste reduction. After a job, give the sheets a quick once-over for any serious damage like deep cuts or cracks.

Here’s a quick-and-dirty checklist for maintenance:

- Clean Them Up: Wipe off all the dust, dirt, and construction muck. It prevents you from dragging one site’s mess onto the next.

- Inspect for Damage: Look for any major tears or punctures. Sheets with a bit of wear and tear can still be used for less demanding jobs.

- Store Them Flat: This is non-negotiable. If you store them on their edge or leaning against a wall, they will bend and warp over time, making them useless for floor protection.

By following these straightforward tips, you’ll ensure that every sheet you get from a supplier in Dubai works harder and lasts longer for you.

Your Questions Answered: PP Corrugated Sheets

We get a lot of questions from project managers and procurement specialists about PP corrugated sheets. It makes sense—you need to get the details right. Here are the answers to the most common queries we hear, giving you the clarity to source pp courragate sheets in dubai without a second thought.

What's the typical cost of PP corrugated sheets in Dubai?

The typical cost of PP corrugated sheets in Dubai varies based on thickness, GSM (grams per square metre), and grade (e.g., standard, UV-treated, or fire-retardant). Bulk order discounts also affect the final price, so it's best to get a direct quote from a specialized building materials distributor for accurate pricing based on your specific needs.

Can we get these sheets with our company branding?

Absolutely. One of the best features of PP corrugated sheets is that they can be easily custom cut to precise dimensions and printed with high-quality company branding. This turns protective coverings or site hoardings into effective advertising tools.

Think about it—every protective floor covering or temporary hoarding on your construction site becomes a billboard for your brand. It’s a smart, simple way to boost visibility while you work. Just let your supplier in Dubai know what you have in mind.

Are PP corrugated sheets a green choice?

Yes, PP corrugated sheets are a solid green choice for projects because polypropylene is 100% recyclable. Furthermore, their durability allows for reuse across multiple job sites, significantly reducing construction waste and helping projects align with UAE construction standards and green building goals.

By choosing reusable and recyclable PP corrugated sheets, contractors not only protect their assets but also contribute directly to the UAE's sustainability goals, turning a simple material choice into a powerful statement of environmental responsibility.

How fast can I get a delivery in the UAE?

Leading distributors in Dubai typically offer very fast delivery, often providing same-day or next-day service for in-stock items. This rapid turnaround helps keep projects on schedule, but you should always confirm the exact delivery timeline with your supplier for your specific location in the UAE.

For a reliable supply of high-quality pp courragate sheets in dubai with expert support and fast, site-direct delivery, trust Yasu Trading Co. LLC. Explore our full range of construction materials and see how we can keep your project moving forward by visiting https://yasutrading.com.